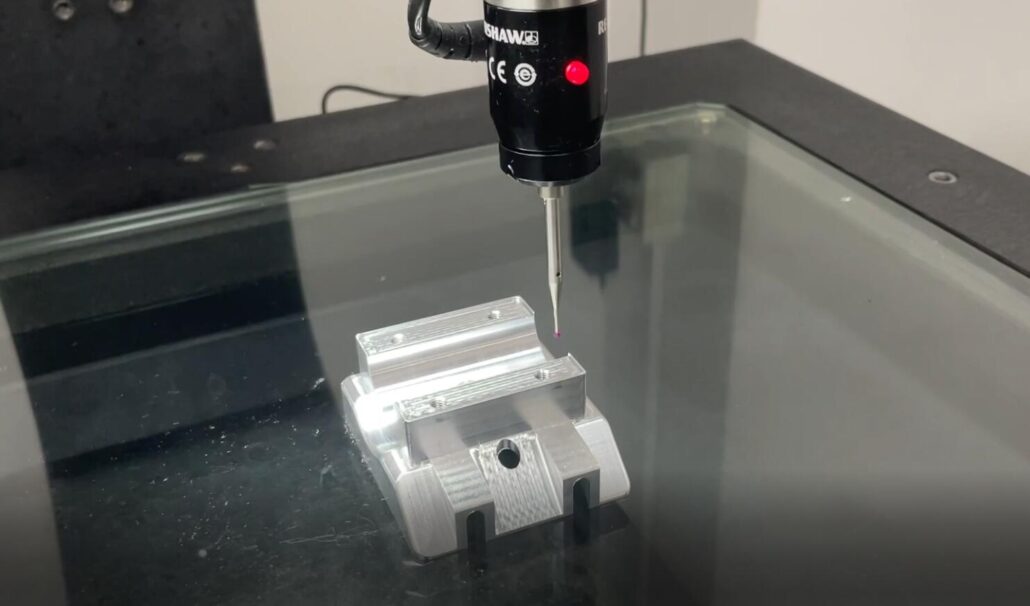

What Is CNC Prototyping? CNC aluminum prototyping is a popular method for creating prototypes. The process is mostly automated and requires little manual work, but a well-experienced user can still be an invaluable asset in creating a high-quality part. An experienced user will also be aware of the intricacies of different materials, as well as…

Is Aluminum A Common Prototyping Material? If you’re a product designer, you’re probably wondering, “Is aluminum a common prototyping material?” If so, you’re not alone! Aluminum is often used for prototype manufacturing due to its outstanding qualities, including corrosion resistance and strength. This makes it a highly suitable choice for various projects, from pre-production prototypes…

According our experience : 1: Quote speed If quantity lower 10 products , can’t quote within 8-10hours , it means can’t reply within working day , i think this is not real factory , most likely is a trade company , because they need wait other company quote , then quote to customer . so…

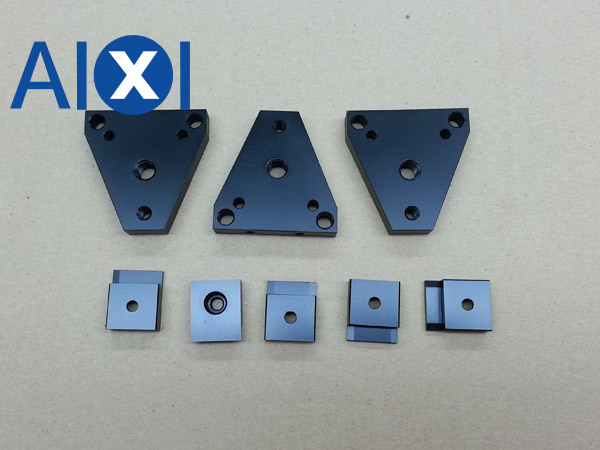

1 Appearance The appearance of the coating is consistent in color and lustre, and the crystals are fine; the coating has no blistering, peeling, pinholes, and burning; no obvious roughness and burrs; no obvious water marks and fingerprints. 2 Plating thickness The thickness of the coating on the main surface meets the requirements of the…

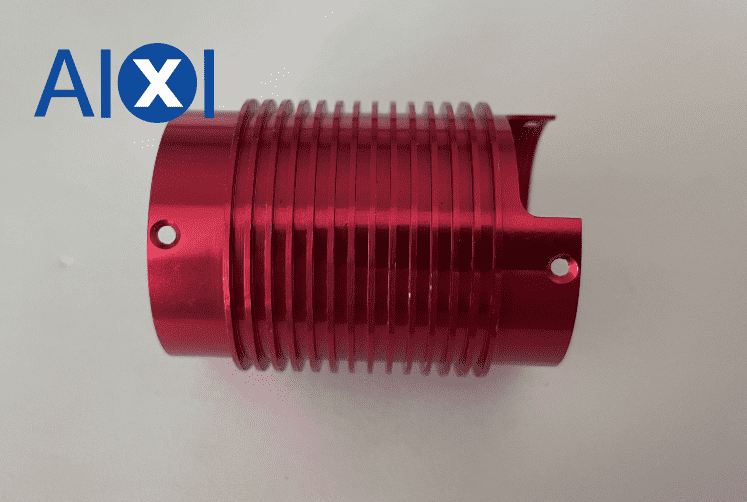

Aluminum oxidation treatment is a processing technology that many aluminum products will choose. It can make the aluminum surface obtain a high-quality protective film and have certain decorative properties. What are the characteristics of aluminum anodized film? 1. High strength The strength of pure aluminum anodic oxide film is higher than that of aluminum alloy…

With the help of oxidation treatment, metal materials can be given a bright appearance, excellent corrosion resistance, wear resistance, insulation and other characteristics, and then achieve various design requirements. At this stage, the most common application is the oxidation treatment of aluminum alloys. Considering that the oxide film of aluminum has a fine structure, good…

Under the corresponding processing technology standards, aluminum parts will form an oxide film on the surface of aluminum parts due to the influence of external current. In order to get rid of the defects of low surface strength and durability of aluminum products, increase the scope of use and increase the service life, the metal…

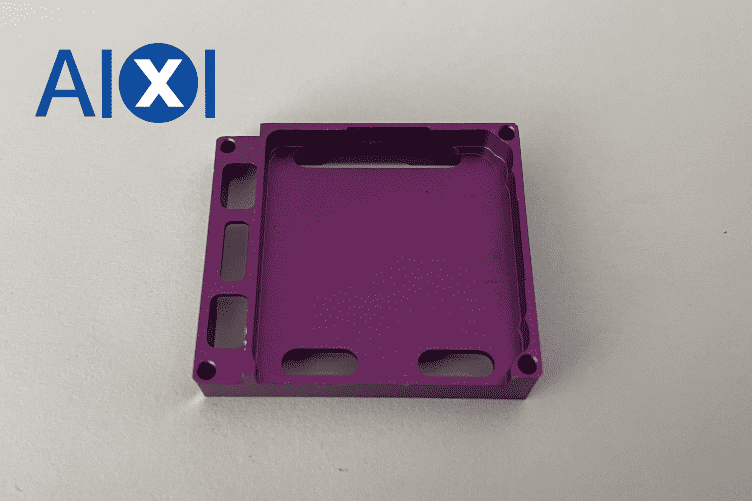

Anodizing coloring is one of the most common processes in aluminum oxidation treatment. It can bring excellent corrosion resistance and decoration to aluminum products. So what should be paid attention to in the process of aluminum anodizing coloring and before and after? 1. Do a good job of cleaning after coloring If the surface of…

Metals may seem hard, but given enough time, even pure air can dissipate them. Oxygen reacts with aluminum alloys to form rusted metal oxides, but now it turns out that metal oxides may save aluminum alloy life. Research has found that aluminum can be protected from further oxidation by a thin film of aluminum oxide,…

What is aluminum anodizing? Anodizing is a relatively simple electrochemical process that has been used for nearly a century to increase the thickness of native oxide layers on aluminum surfaces. Aluminum Anodizing is a strong and durable finish that maintains the beauty and natural metallic luster of aluminum while enhancing its natural ability to withstand…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español