Vacuum Casting Service

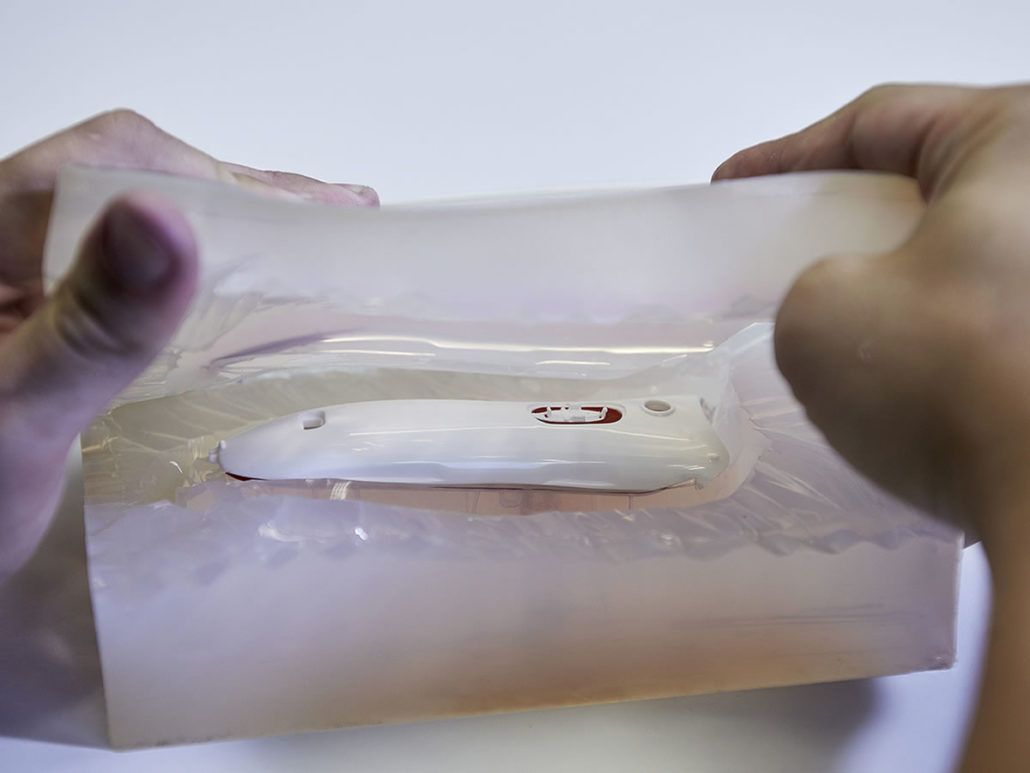

Nowadays, the world advocates environmental protection, and the selection of silicone molds is also very much. The silicone mold is a very environmentally friendly process, and the products produced are transparent, and can also be made according to the color specified by the customer. The color selectivity is more than that of the injection molding. In terms of silicone molds, the production time is very fast. Generally, it can be finished on the same day. It can achieve higher precision products, and the surface of the product is very smooth. It is not necessary to make surface treatment again. If other special surfaces are needed, we You can also choose to make a spray paint.

In general, vacuum casting is very advantageous for the production of prototypes and the production of small batches.

Contact us for more information .

Advantages of Vacuum Casting

1: Vacuum casting is also a process of rapid prototyping. It’s not like making a mold for a long time, but a few days to complete the product.

2: The choice of color is more diversified, and the surface of the produced product is very smooth. It is also possible to make very large products.

3: Compared with 3D printing, CNC machining and so on , the price of silicone mold is the cheapest one, which is also a great advantage for product development.

4: The production of prototypes and small batches currently has a big advantage.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español