The machine’s adaptability to CNC has brought revolutions in the manufacturing process. These machines have made metal work easier and quicker. There are different types of CNC machines. Understanding the applications of CNC machining can open doors to new efficiencies. Interestingly, the usage of CNC machines has become standard. Many industries consider these machines…

Category Archives: CNC Machining

We will share cnc machining knowledges , if you are interiesting for us , welcome focus on our website , and i believe you can learn you want .

The CNC machine has revolutionized metalworking. The manufacturing process used to take days and is now completed in minutes. Different CNC-based machines are out and helping the manufacturers. However, 3-axis vs. 5-axis CNC machines have been a hot topic for discussion. Both are suitable for various applications, but which one is better? Interestingly, both…

Introduction CNC machining has already won the race because of its high accuracy. Whether you use plastic or solid materials, this subtractive manufacturing eliminates unnecessary margins and produces a perfect material. One of the most popular materials is PEEK— a thermoplastic polymer. It offers excellent applications due to elegant corrosion resistance and strength. …

Introduction Walking through the empire of industrial sectors gets you jaw-dropping facts. Hundreds of machines work under one control system and continuously produce quality products. This accuracy in precisions kneels to the CNC machines, which have been undefeated for decades. Over time, CNC machining has provided manufacturers with enhanced efficiency and fast production. Today, we…

Introduction Technology is rising every day. You can find many CNC machines that assist in cutting and removing some pieces and reaching the highest efficiency levels. You get 100% accuracy in the cutting and planning of the workpiece. Machining is the top option available to the manufacturers. But it is present in different…

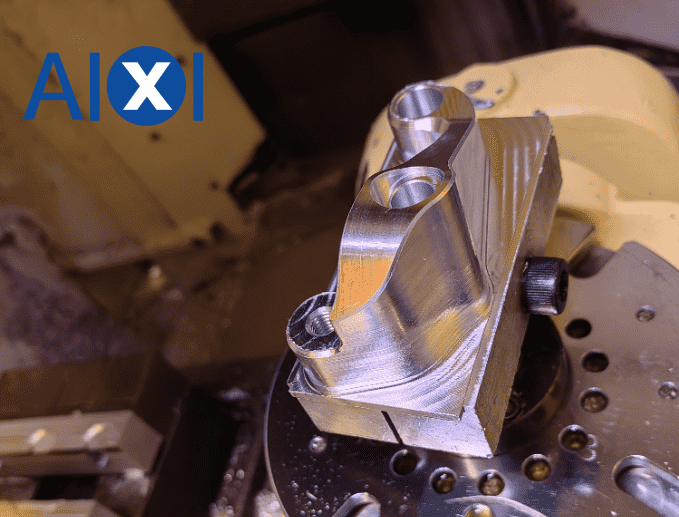

Properties and characteristics of aluminum Aluminum is a light, malleable silvery white metal with good electrical and thermal conductivity. In the field of machining, aluminum is widely used because of its low density, high plasticity and good machinability. However, aluminum also has some unique processing challenges, such as its high thermal conductivity may lead to…

Computer numerical control (CNC) machining is a crucial process in manufacturing, enabling the precise cutting and shaping of various materials. The success of any CNC machining project depends heavily on the choice of material. Selecting the right material ensures the desired functionality, durability, and cost-efficiency of the final product. With so many options available, choosing…

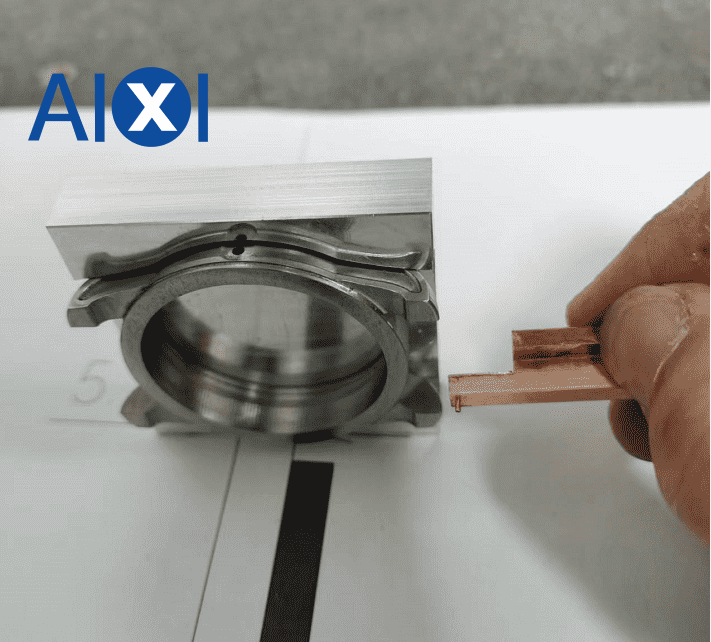

The CNC cutting service refers to the workpiece instruction (or program) used to control machine tools or equipment, which is a new control method given in digital form. When the instruction is provided to the control device of the CNC automatic cutting machine, the cutting machine can automatically cut according to the given program. Numerical…

CNC machining, also known as Computer Numerical Control machining, is a subtractive manufacturing process that involves the use of computer-controlled machines to remove material from a workpiece to create a desired shape or part. This technology has revolutionized the manufacturing industry, allowing for precise and efficient machining of complex parts with high accuracy and repeatability….

1. Introduction 1.1 Overview of Precision CNC Machining Precision CNC machining is at the vanguard of contemporary production, transforming sectors with unmatched efficiency and accuracy. This state-of-the-art technology uses computer-controlled machinery to create complex parts with amazing accuracy, propelling breakthroughs across several industries. Precision CNC machining is essential to improving performance, quality, and innovation in…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español