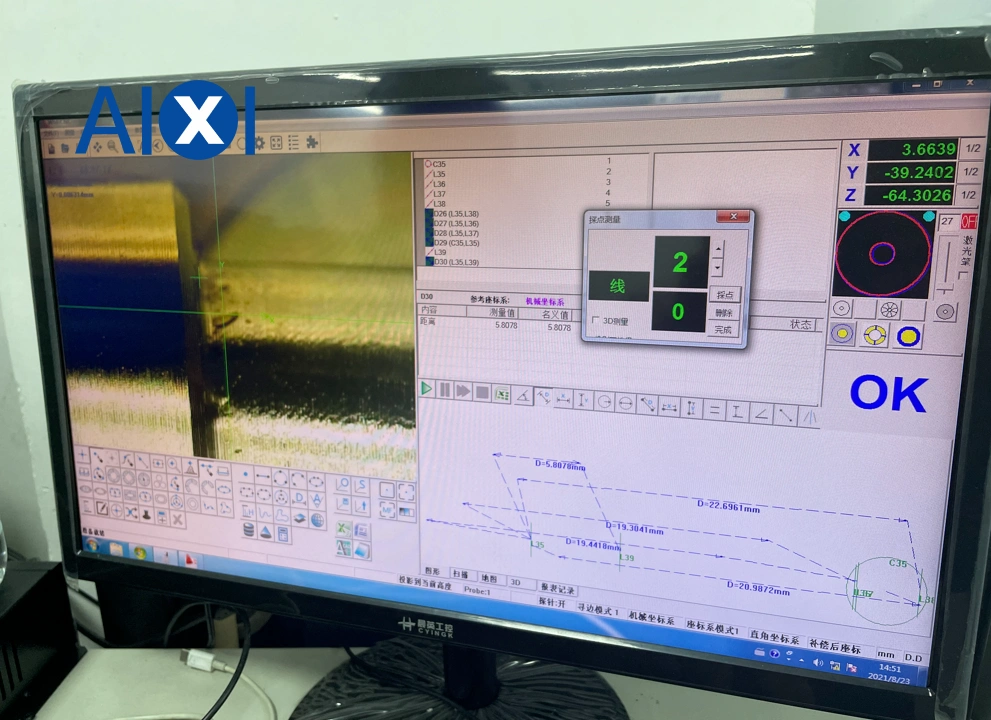

On-Site Inspection

QC people will checking on-site all parts every two hours, this is very important work during produce.

Go-no go fixed gauges | Ring gauge

Thread test also is very imortant point, surface finishing will affect this thread ,for example, Anodized, Plating, Heat treatment. So we need to control this thread tight/loose during machining, Ensure that all thread is ok after go-no go fixed gauges | ring gauge checked.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español