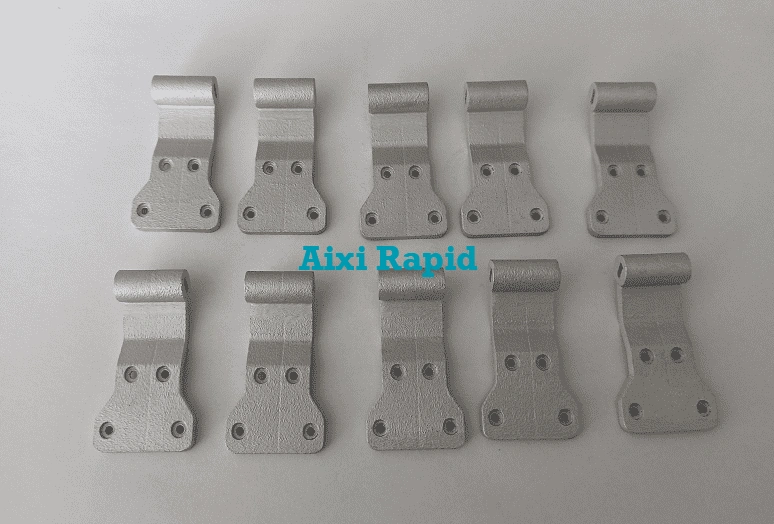

Additive Manufacturing – Industrial 3D Printing

3D printing usually refers to a series of additive manufacturing services such as SLA, SLS, SLM, FDM, etc. We can make 3D printing of plastic and metal. For some hollow products and especially complex products, only 3D printing can be made. This is also a bigger advantage than CNC machining, and the price is relatively cheap, so it also saves a lot of cost in the production and testing of the prototype.

Contact us for more information.

Advantages of 3D Printing

1: Compared to mold and CNC machining, 3D printing is the cheapest way to make prototypes and small batch productions, because it is almost just the cost of a material.

2: Being able to make more complex and hollow products is one of the biggest advantages of 3D printing.

3: The processing time is very fast, and the error rate is very low. It is printed directly according to the 3D drawings designed by the customer. The mold and CNC need pre-programming, design inspection, production fixture and so on.

4: 3D printing does not waste the use of materials, how much material is used in the product, and how much material is used, and CNC machining requires a lot of waste.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español