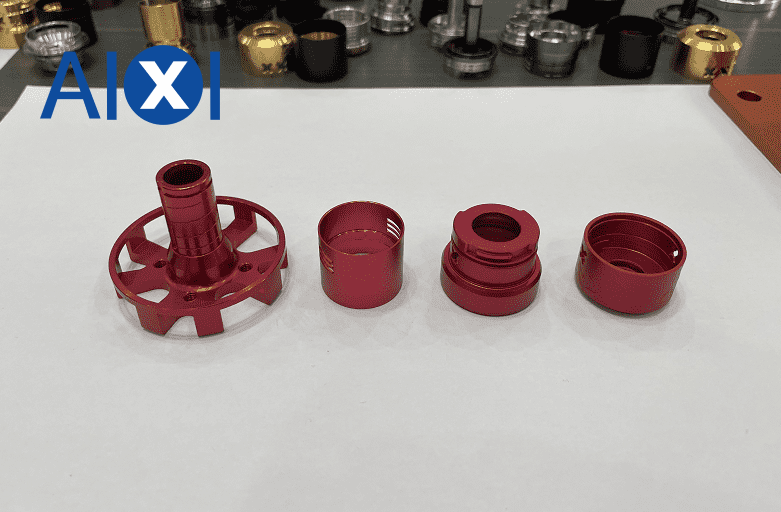

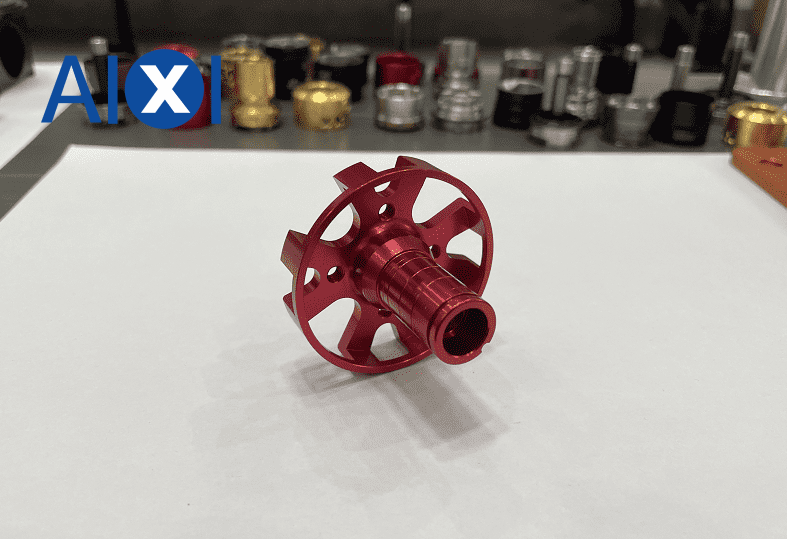

What Are the Benefits of Anodizing Aluminum? What are the benefits of anodizing aluminium? Anodizing aluminum improves the hardness of the material and reduces friction. Anodising aluminum is an environmentally friendly option compared to electroplating, spraying or etching. Anodizing aluminium is also more reflective than etched aluminum. It is used to coat the exterior of…

Does Anodized Aluminum Wear Off? Does anodized aluminum wear off? The answer to this question depends on what you consider “additive”. A lot of people say that this process isn’t addictive, but the truth is that it can be. This process gives aluminum its characteristic metallic look, and its color is extremely durable and resistant…

AIXI company has launched a new material for 3D printing, yellow engineering material ABS, which has the characteristics of good precision, small deformation and shrinkage, both strength and toughness, and high temperature resistance. Looking forward to your inquiry!

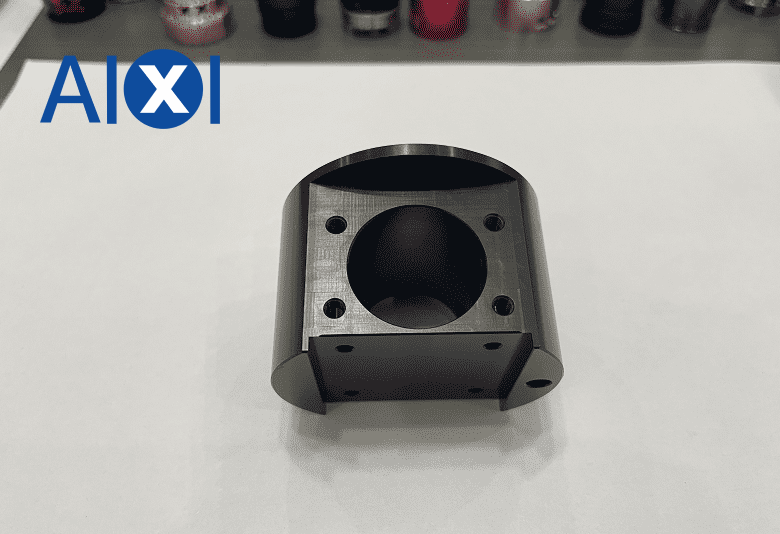

CNC Electronic Cigarette Parts If you are looking for the best and most reliable source of CNC E-cigarette parts, you are in the right place. There are several online sources for you to choose from. They offer different types of electronic cigarette parts at competitive prices. You can also opt to have your custom electronic…

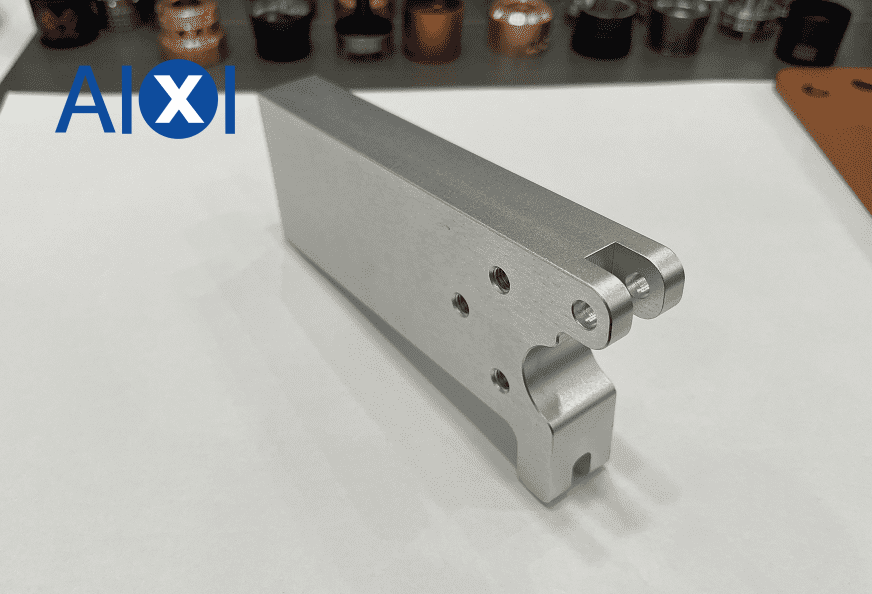

What Kind of Aluminum Is Used For CNC Machining? Several factors affect the choice of material for CNC machining. For example, the type of aluminum used depends on its mechanical properties. There are several types of aluminum, including 6061, 7075, 2024-T3, and 5052. The article below explains the benefits and disadvantages of each one. Once…

What is CNC Machined Aluminum? You may have heard about the benefits of CNC machined aluminum parts, but do you know exactly what it is? Aluminum is nonmagnetic, soft, and malleable. Yet, it has exceptional corrosion resistance and is a popular material used in many industries. Read on to learn more about this alloy. CNC…

How Thin Can You CNC Aluminum? If you’ve ever wondered how to CNC aluminum, you might have wondered whether you should use straight-flute bits or fluted end mills. While both types of cutters can cut aluminum, wood can be faster to cut. However, wood can suffer from Radial Chip Thinning if you cut it less…

Can You CNC 6061 Aluminum? There are many different alloys made from aluminum, but there is one grade that is particularly well-suited for CNC machining: 6061. This grade of aluminum is commonly called “tooling plate” and has the right properties to maintain a high level of flatness. However, 6061 is still the most popular aluminum…

How Strong Is CNC Aluminum? If you’re looking to buy a CNC aluminum cutting machine, you may be wondering how strong it is. Here are a few of the things to consider: 180Mpa, Non-magnetic, Good conductor of heat and electricity, and Machinability. Using the right bit for your CNC aluminum cutting machine is essential for…

Can You CNC Aluminum? Can you CNC aluminum? Yes, you can. However, there are several things to keep in mind. Aluminum is extremely difficult to cut and requires high-quality tooling. Here are a few tips for cutting aluminum. First, don’t forget to lubricate the cutting tool. Aluminum will stick to the bit if it’s not…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español