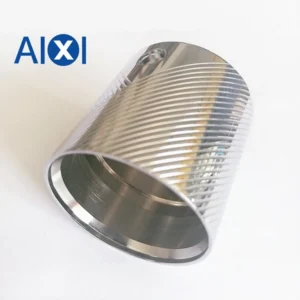

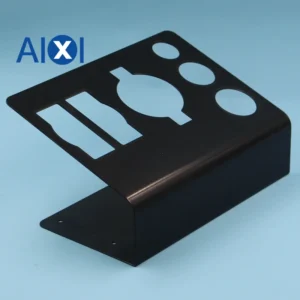

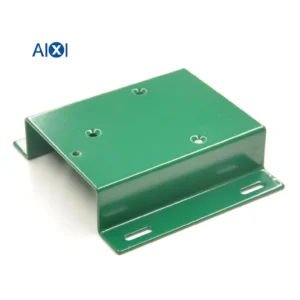

AIXI Surface Finishing Services Supplier

Metal surface treatment is a method of changing the surface characteristics of metal materials through specific techniques. It can improve the performance and appearance of metals, improve corrosion resistance, wear resistance, aesthetic appearance, and bonding with other materials. Common surface finishing processes include electroplating, spraying, anodizing, and passivation. These processes provide long-lasting protection and excellent performance for products in the manufacturing industry. AIXI provides CNC machining services, and we also post-process parts to improve them.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español