Differences between ABS plastic and POM: 1. The characteristics of the two are different: 1. Characteristics of ABS plastic: ABS has excellent composite physical and mechanical functions and particularly good low temperature impact resistance. Dimensional stability. Electrical performance, abrasion resistance, chemical resistance, dyeing, finished product processing and mechanical processing are all good. ABS resin has…

Category Archives: Plastic Material

Delrin (POM), PC, PA, PP, ABS, PMMA, PPSU, PEEK, PEI, PVC, Teflon, PEHD, PTFE

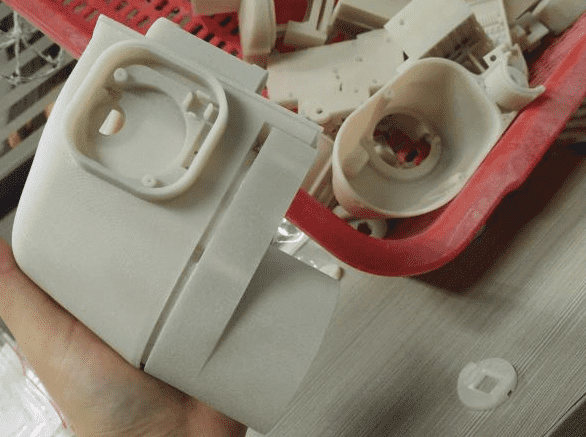

AIXI company has launched a new material for 3D printing, yellow engineering material ABS, which has the characteristics of good precision, small deformation and shrinkage, both strength and toughness, and high temperature resistance. Looking forward to your inquiry!

In recent years, PP fiber reinforced materials have developed rapidly in the modified plastics industry, and most of the glass fiber reinforced materials used in the automotive field are PP substrates. With the improvement of plastic modification technology and the needs of the development of the automotive industry, the development trend of long glass fiber…

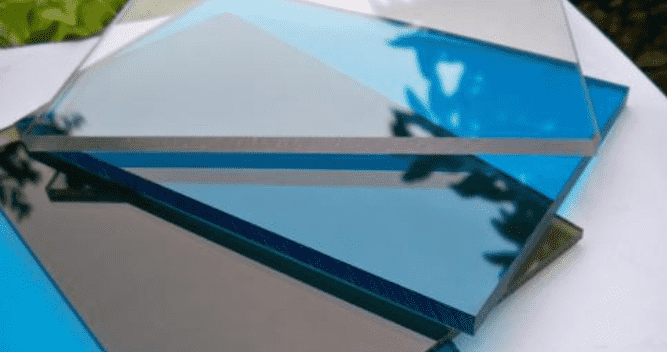

(Polycarbonate) Specific gravity: 1.18-1.20 g/cm3 Molding shrinkage: 0.5-0.8% Molding temperature: 230-320℃ Drying conditions: 110-120℃ 8 hours Material performance High impact strength, good dimensional stability, colorless and transparent, good colorability, electrical insulation, corrosion resistance, wear resistance, but poor self-lubricity, stress cracking tendency, easy to hydrolyze at high temperature, poor compatibility with other resins . Suitable for…

(Polyamide) Specific gravity A6-1.14g/cm3 PA66-1.15g/cm3 PA1010-1.05g/cm3 Molding shrinkage rate A6-0.8-2.5% PA66-1.5-2.2% Molding temperature: 220-300℃ Drying conditions: 100-110℃ for 12 hours Material performance Tough, abrasion-resistant, oil-resistant, water-resistant, anti-enzyme bacteria, but high water absorption. Nylon 6 has good elasticity, high impact strength, and greater water absorption. Nylon 66 has better performance than nylon 6, high strength and…

(Polyethylene) Specific gravity: 0.94-0.96 g/cm3 Mold shrinkage: 1.5-3.6% Molding temperature: 140-220℃ Material performance Corrosion resistance, excellent electrical insulation (especially high-frequency insulation), can be chlorinated, modified by irradiation, and can be reinforced with glass fiber. Low pressure polyethylene has a melting point, rigidity, hardness and strength, low water absorption, and good The electrical properties and radiation…

(Polypropylene) Specific gravity: 0.9-0.91 g/cm3 Mold shrinkage: 1.0-2.5% Molding temperature: 160-220℃ Material performance Low density, strength and rigidity, hardness and heat resistance are better than low-pressure polyethylene, and can be used at about 100 degrees. It has good electrical properties and high-frequency insulation. It is not affected by humidity, but it becomes brittle at low…

(Polyoxymethylene) Specific gravity: 1.41-1.43 g/cm3 Mold shrinkage: 1.2-3.0% Molding temperature: 170-200℃ Drying conditions: 80-90℃ 2 hours Material performance It has good overall performance, high strength and rigidity, good wear resistance, low water absorption, good dimensional stability, but poor thermal stability, easy to burn, and easy to age when exposed to the atmosphere. Suitable for making…

(Polystyrene) Specific gravity: 1.05 g/cm3 Mold shrinkage: 0.6-0.8% Molding temperature: 170-250℃ Material performance Excellent electrical insulation (especially high-frequency insulation), colorless and transparent, light transmittance second only to plexiglass, coloring, water resistance, and good chemical stability. The strength is moderate, but the quality is brittle, and it is easy to cause stress brittleness. Resistant to benzene,…

ABS plastic (Acrylonitrile Butadiene Styrene) Specific gravity: 1.05 g/cm3 Mold shrinkage: 0.4-0.7% Molding temperature: 200-240℃ Drying conditions: 80-90℃ 2 hours Material performance 1. Good overall performance, high impact strength, chemical stability, and good electrical properties 2.Good weldability with 372 plexiglass, made of two-color plastic parts, and can be chrome-plated and painted. 3. There are high…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español