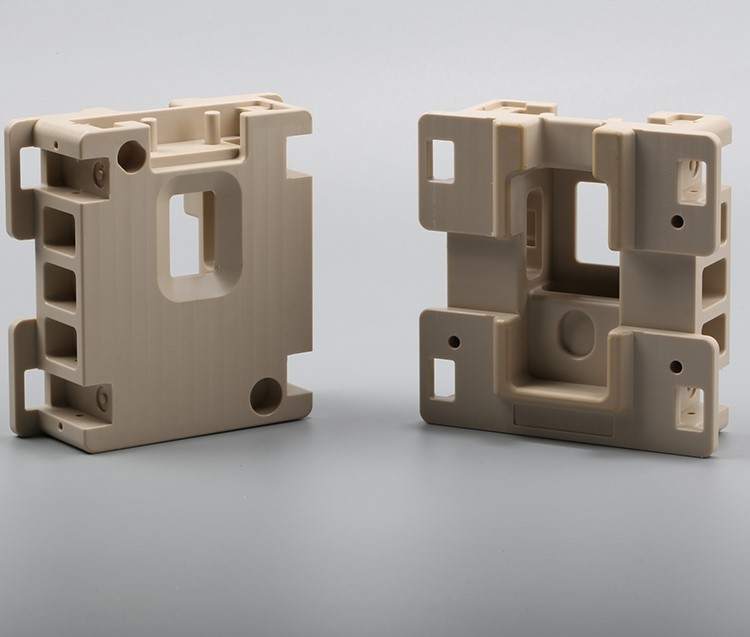

What’s The Advantage CNC Machining PEEK Products ?

1. Excellent chemical resistance and water resistance

2. Low hygroscopicity

3. Abrasion resistance and abrasion resistance

4. Excellent resistance to gamma rays and X-rays

5. Some models are biocompatible (medical grade)

6. Resistant to biodegradation, highly resistant to thermal (unaffected by continuous hot water and steam exposure) degradation

7. High precision (tight tolerances)

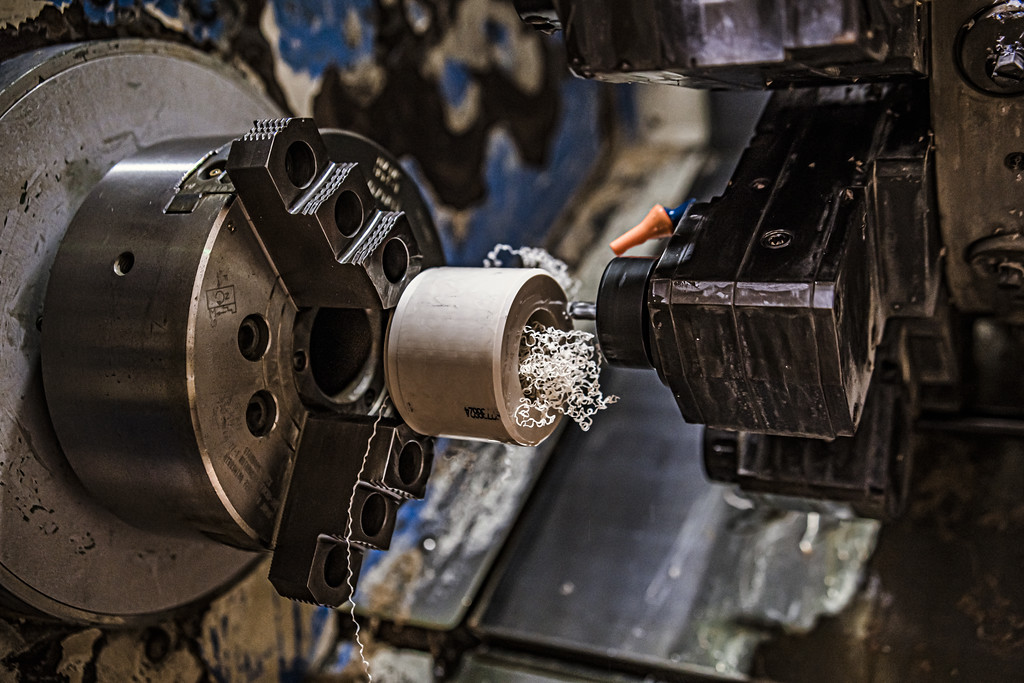

8. Relatively high melting point allows faster feed and speed

9. A lightweight alternative to most metals

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español