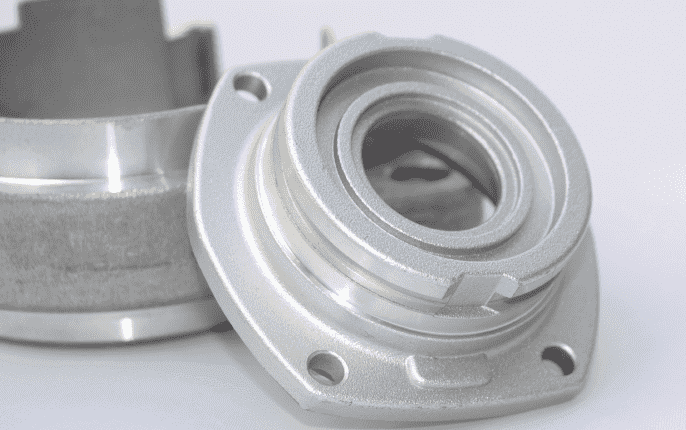

Die Casting Services

Casting is a process in which a liquid or semi-solid metal or alloy, or a liquid metal or alloy containing a reinforcement phase, is filled into the cavity of the die-casting mold at high speed under high pressure, and the metal or alloy is under pressure A casting method that solidifies to form a casting.

The commonly used pressure during die casting is 4 ~ 500MPa, and the metal filling speed is 0.5-120m / s. Therefore, high pressure and high speed are the fundamental difference between the die casting method and other casting methods, and are also important features.

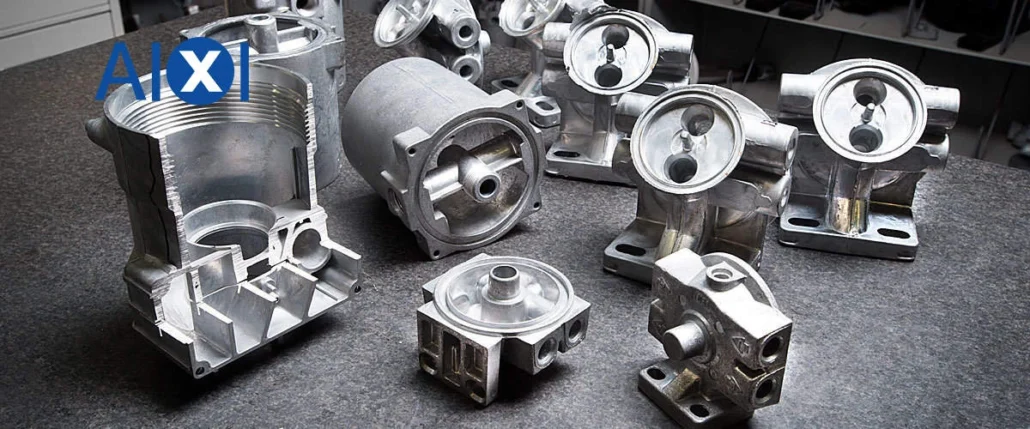

AIXI Hardware has good experience in pressure casting, and has a large casting partner, so we also have a lot of product cases in casting, including car brake discs, coffee machine parts, office machinery, production watch bodies, automotive Accessories, pipe fittings, motors, electrical appliances, etc.

Advantages of die casting

1: Various castings with complex shapes can be cast, such as box, frame, bed, cylinder block, etc.

2: The size and quality of castings are almost unlimited, castings as small as a few millimeters, a few grams, as large as a dozen meters, and hundreds of tons can be cast.

3: Any metal and alloy castings can be cast.

4: The casting production equipment is simple, the investment is small, and the raw materials for casting are widely available, so the casting cost is low.

5: The shape and size of the casting are close to the parts, so the workload of cutting processing is reduced, and a lot of metal materials can be saved.

Why choose AIXI Hardware for Pressure Die Casting ?

Maybe this is strange feel for you choose AIXI die casting. because for AIXI Hardware, we are focus on high precision CNC machining . but please see this is choose AIXI’s advantage:

1:We have rich metal casting experience engineers, and already made lot of die casting products.

2:We have CNC machine , because lot of die casting products need precision machining, so we can do some machining step .

3:We have long die casting factory partner, and our supplier no trade bussiness, so for AIXI , this is good connect to make good casting product for you.

If you are interiesting for our casting bussiness, welcome contact us.

Common Pressure Die Casting Materials

ALuminum: (ADC12, A380, ADC10 and A413), Advatage: Strong, Light Weight, And can make highly polishing.

Zinc: (Zinc #3 and #5 Alloy), Advatage: Cheap, and can make plating.

Magnesium: (AZ91D), Advantage: Offer best strength-to-weight ratio.

Classification of die casting

1 Ordinary sand casting, using sand as a mold material, also known as sand casting, sand turning, including three types of wet sand, dry sand and chemically hardened sand, but not all sand can be used for casting. The advantage is that the cost is lower, because the sand used in the mold can be reused; the disadvantage is that the mold is time-consuming, the mold itself cannot be reused, and it must be destroyed to obtain the finished product.

2 Special castings can be divided into special castings with natural mineral sandstone as the main modeling materials (such as investment casting, mud casting, shell casting, negative pressure casting, solid casting, ceramic casting, etc.) And special casting with metal as the main mold material (such as metal mold casting, pressure casting, continuous casting, low pressure casting, centrifugal casting, etc.).

1.1 Sand mold (core) casting method: wet mold sand, resin self-hardening sand mold, water glass sand mold, dry and surface dry mold, solid mold casting, negative pressure molding.

1.2 Sand core manufacturing method: It is selected according to the sand core size, shape, production batch and specific production conditions. In production, it can be divided into manual core making and machine core making.

2.1 Metal mold casting method

Use a metal with a higher melting point than the raw material to make a mold. Among them are subdivided into gravity casting method, low pressure casting method and high pressure casting method.

Limited by the melting point of the mold, the metals that can be cast are also limited.

2.2 Dewaxing casting method

This method can be an outer film casting method and a solid casting method.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español