Because aluminum alloys have a severe tendency to oxidize and inhale, they are directly in contact with furnace gas or the outside atmosphere during the smelting process. Therefore, if the control is slightly improper during the smelting process, the aluminum alloy can easily absorb gas and form pores, the most common It is a pinhole….

Category Archives: Die Casting

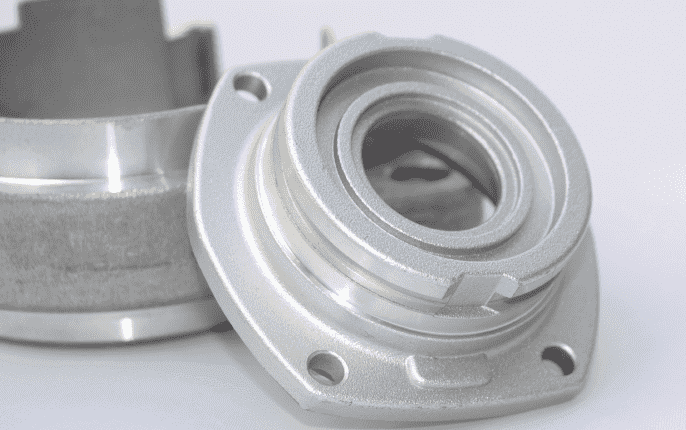

For Some Functional parts and have a big quantity request ,use die casting do it will good choice .

In the production process of aluminum alloy castings, stomata defects often occur due to improper operation or unskilled processes. Once the blowhole appears, it will often cause the casting to be scrapped due to quality problems and increase production costs. However, there are many reasons for the blowhole defects in aluminum alloy castings. Many companies…

Aluminum casting is divided into aluminum alloy casting and high-pressure casting in general. It is often said that die casting refers to high-pressure die casting, which uses a die-casting machine to compact the molten aluminum alloy profile in a high-speed mold and rapidly cool it under high pressure. And usually casting is divided into sand…

In the process of aluminum alloy gravity casting, as the shape of its castings is different, the casting molds of its products are also different. Even if it is the same part, the mold form is often different with different casting processes, but in any case Aluminum alloy gravity casting molds still have their commonalities….

The material of the aluminum shell is an aluminum alloy material, which becomes a shell through manufacturing processing. This device is widely used in society, and it is also involved in the industry. It is mainly used as a shell for good protection, or for panels, brackets, etc. The protection effect of the aluminum shell…

Die casting (note that die casting is not the abbreviation of pressure casting) is a metal casting process, which is characterized by using a mold cavity to apply high pressure to the molten metal. The mold is usually made of a stronger alloy, and the process is somewhat similar to injection molding. Sand mold casting…

Mold material selection is a very important part of the entire mold making process. The selection of materials for the mold needs to meet three principles. The mold should meet the work requirements of wear resistance and toughness. The mold should meet the process requirements. At the same time, the mold should meet the economic…

Low-pressure casting is a kind of equipment that is often seen in the industry and is a special process. Many times we will pay more attention to the manufacturing process of low-pressure casting. Let’s take a look at what will happen to the process of low-pressure casting Factors influence it. What factors affect the process…

Molding: the process of leaving the mold under the action of the ejection mechanism Beer: mold angle or draft angle Undercut: the position where the mold cannot be pulled out vertically because of the side angle or the concave position Die layout: the schedule of the mold Zheng Ge: A mold structure in which the…

Aluminum castings are used in detail, construction, hardware, equipment, engineering machinery and other large machinery, machine tools, ships, aerospace, cars, locomotives, electronics, computers, electrical appliances, lamps and other occupations, many of them are ordinary people touching all day, but not Understand the metal objects. Common problems with aluminum castings: 1. The shortcomings of cast aluminum…

- 1

- 2

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español