What is CNC Machined Aluminum?

You may have heard about the benefits of CNC machined aluminum parts, but do you know exactly what it is? Aluminum is nonmagnetic, soft, and malleable. Yet, it has exceptional corrosion resistance and is a popular material used in many industries. Read on to learn more about this alloy. CNC machined aluminum alloys are used for a variety of parts and components in the engineering industry. These components are incredibly durable, lightweight, and highly customizable.

Aluminium is a non-magnetic metal

Aluminum is a light, non-magnetic metal that is one of the third most abundant elements in Earth’s crust. Its low density and resistance to corrosion make it an excellent choice for various applications, including the aerospace, transportation, electrical, and building industries. It is also widely used in the manufacture of household goods, including kitchenware, electronics, and appliances. Aluminum is generally non-magnetic, but can become corroded if exposed to long-term exposure to salt, which will result in a chalky white residue.

When CNC machining aluminium, tool geometry is a significant factor in the process. It is best to choose tools with two to three flutes, with two being optimal for high chip clearance and three being the ideal balance between chip clearance and tool strength. Typically, the higher the flute count, the smaller the chip valleys will be. CNC machining aluminum alloys require cutting tools with between two and three flutes.

It is soft

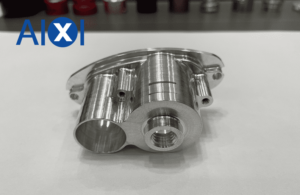

CNC machined aluminum is a highly versatile and durable material. Its silvery or gray appearance and low density make it an excellent choice for a wide variety of industrial applications. In addition, it is nonmagnetic and has a low density, making it ideal for precision machining. Furthermore, it has an incredibly high strength to weight ratio and is resistant to corrosion when treated with an anodized finish. Fortunately, this characteristic makes it a very popular choice for CNC machining.

Although aluminum is soft by nature, CNC machined tools made from carbide are most appropriate for aluminum machining. A key feature of carbide tools is the ability to retain a razor sharp edge. Both carbide grain size and the binders in carbide workpieces play an important role in this. Larger grain sizes produce a harder material while small grains are more impact-resistant. However, to obtain a fine grain structure, cutting fluids containing cobalt should be used.

It is malleable

CNC machined aluminum is a popular choice for a variety of applications. Its malleability makes it easy to machine, and its high machinability means it can be machined quickly and with tight tolerances. These characteristics make it a great choice for businesses looking to minimize their expenditures and materials resources while minimizing environmental impact.

ABS, another popular material for CNC machining, is a very lightweight metal with excellent machinability properties. ABS is excellent for 3D printing applications because it’s lightweight but still has above-average impact strength. PP, HDPE, and PCGF30 are other plastics that can be machinized but lack the strength of aluminum. The benefits of aluminum CNC machining are maximized by combining it with other manufacturing processes, and can make aluminum an excellent choice for complex shapes.

It is durable

CNC machined aluminum is durable and inexpensive. This lightweight material has a high strength-to-weight ratio and is used in many different industries. It is scratch-resistant and resistant to corrosion even under common atmospheric and marine conditions. Depending on the material grade, CNC machined aluminum can also have anodizing applied to improve its properties. Its low cost and high resistance to rust make it an economical choice for many applications.

Because of its high thermal expansion and low hardness, aluminum is prone to deformation when machined into thin parts. Aluminum should be subjected to a low concentration of heat, but should dissipate the heat quickly. In addition, if the aluminum alloy plate is cnc machined, it should be processed within the same time frame. This will ensure that the finished product has the same amount of strength, and is more resistant to the effects of heat and wear.

It is machinable

CNC machined aluminum is one of the most popular metals for machining. Its high machinability is one of the most significant benefits of this material, and makes it an excellent choice for many industries. Its high machinability allows it to be machined to close tolerances. The advantages of CNC aluminum machining include fast machining times, lower labor costs, and tight tolerances. Compared to other metals, aluminum is also lightweight and can be machined to almost any shape.

In the manufacturing industry, CNC aluminum is more common. Aluminum alloys are relatively cheap and easy to machine, and come in a variety of grades. CNC machines can produce nearly any three-dimensional object. Here are some of the advantages of CNC aluminum machining:

It is recyclable

Metalworking companies create enormous amounts of waste material. Chips of aluminum are generated during machining operations. These chips are collected in metal tipping bins next to CNC machines. They are then processed and compacted to increase the value of aluminum scrap. CNC machined aluminum is a recyclable material, but it must be processed properly in order to be a valuable commodity. These steps reduce the volume of waste material and improve the price of aluminum scrap.

Another major advantage of CNC machined aluminum is its high recyclability, making it a great choice for businesses trying to reduce their environmental impact and material wastage. CNC machining generates a large amount of scrap material, primarily in the form of chip material from cutting tools. In some cases, this could lead to a desire by businesses to look for alternatives to aluminum. The drawbacks of CNC machined aluminum are that it is generally more expensive than steel and requires a lot of energy to process.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español