Five-axis machining CNC center CNC machine tool is a high-speed, high-efficiency, and cost-effective production equipment. It is easy to operate, has a simple process, and greatly reduces labor waste. However, sometimes failures such as unstable processing accuracy may occur under internal or external conditions. The reasons for the unstable processing accuracy of CNC machine…

As the economy develops and the consumption structure continues to upgrade, consumers have higher requirements for the appearance and quality of various products, pay more attention to quality, and present the characteristics of personalized, diversified, high-end, and experiential consumption. Therefore, the surface treatment of workpieces in our hardware industry has become particularly important, not only…

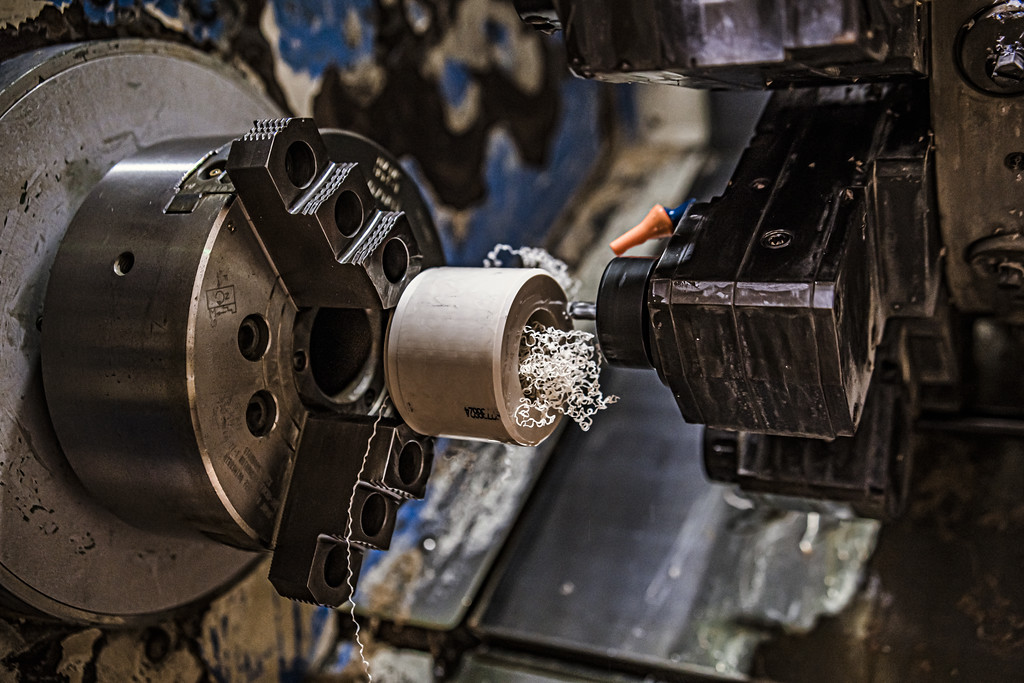

Precision-manufactured CNC machining technology The application of CNC technology has brought about qualitative changes in traditional manufacturing. In recent years, the development of microelectronics technology and computer technology has given CNC technology new vitality. CNC technology and CNC equipment are an important foundation for the industrial modernization of various countries. CNC machine tools are…

G-code is the most widely used computer numerical control programming language. It is primarily used in computer-aided manufacturing to control automated machine tools and has many variants. G-code instructions are given to the machine controller (industrial computer), which tells the motor where to move, how fast to move, and what path to follow. The two…

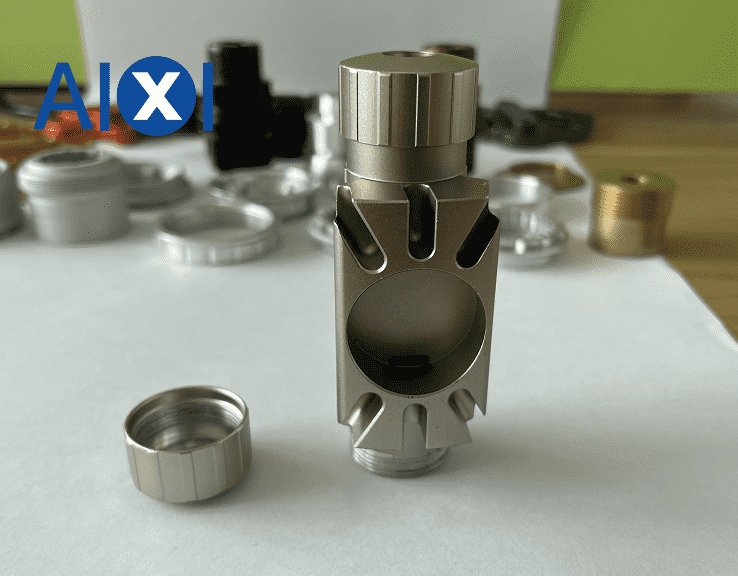

Top Aluminum – Cost-effective Processing of Aluminum Parts If you are looking for a high-quality, high-precision, and fast aluminum CNC machining product manufacturer. You can trust Ashe to be your best choice. We have several high-end five-axis linkage CNC machine tools (a machine tool with high technological content, high precision, and dedicated to processing complex…

The Importance of Machining Tolerances in the Manufacturing Industry Tolerance matching in mechanical manufacturing is a rigorous and complex work, which requires the full attention of mechanical designers and manufacturers. In today’s society, people’s requirements for quality are extremely high. Therefore, in the process of any product manufacturing process, the standard processing tolerance is an…

What are CNC? How does it work? CNC is an acronym for Computer Numerical Control. It is a pre-programmed computer software that directs the operation of factory equipment and machinery. Use subtraction to remove unnecessary parts from a large block of material. Before the advent of CNC machines, the industry operated using manually controlled handwheels…

A threaded rod, also known as a screw or stud, is a cylinder with helical grooves cut into its outer surface or a cone with helical grooves cut into a conical surface, and has threads along its entire length. The screws have different heads, such as outer hexagonal screws, large flat screws, inner hexagonal screws,…

Machining is a process of changing the shape or performance of workpieces with processing machinery. Remove excess material in a controlled manner to produce the desired part. Therefore, machining is also called subtractive manufacturing, and the workpiece is always larger than the finished part. Machining processes allow for greater precision than alternative technologies such as…

Anodizing: Electrochemical oxidation of metals or alloys (most anodizing is done on aluminum and its alloys). Aluminum and its alloys form an oxide film on the aluminum product (anode) under the corresponding electrolyte and specific process conditions due to the action of the applied current. Anodizing generally refers to sulfuric acid anodizing. Alodine treatment: Aluminum…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español