What are CNC? How does it work?

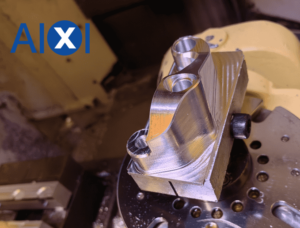

CNC is an acronym for Computer Numerical Control. It is a pre-programmed computer software that directs the operation of factory equipment and machinery. Use subtraction to remove unnecessary parts from a large block of material. Before the advent of CNC machines, the industry operated using manually controlled handwheels or levers. CNC machines, on the other hand, work using a language called g-code, which transmits precise measurements of production, such as feed rates, speeds, positions, and coordination, to the computer itself.

CNC machine tools can produce durable, precise and heat-resistant parts. Casting, metal forming, jewelry, etc. are all its technical applications and are processing instruments favored by most industries.

The number of times the CNC machine tool is used can only be zero or countless times. It produces parts that are strong and dimensionally accurate. Whether it is in engines, aircraft or machinery, or in industries such as engraving, lettering and woodworking, it has its figure.

What are the benefits of CNC machining?

- Accuracy and consistent product quality

The process is more precise and repetitive, it minimizes time consumption, reduces errors in the manufacturing process, and eliminates unnecessary waste.

- High production speed and improved efficiency

Process automation, thereby improving the speed and quality of production.

- Safer machine operators

CNC machine tools work behind transparent safety doors, which are much safer than manually operated machines.

- More cost-effective

Manual machining requires one operator per machine; but CNC requires fewer machine operators, and skilled operators can already run several tools simultaneously.

What products can CNC machine tools manufacture?

- Types of manufactured products

CNC center is a high-precision machine tool equipment that can be used to manufacture various types of products, including but not limited to the following categories:

- Metal parts: CNC centers can process various metal materials, including aluminum, steel, copper, titanium, aluminum alloy, etc., to manufacture various metal parts, such as gears, bearings, cams, etc.

- Plastic parts: CNC centers can also process various plastic materials, such as polyethylene, polypropylene, polyurethane, etc., to manufacture various plastic parts, such as shells, brackets, etc.

- Wood products: CNC centers can also be used to process wood to manufacture various wood products, such as furniture, stairs, doors and windows, etc.

- Electronic components: CNC center can process various electronic components, such as circuit boards, chassis, etc.

- Mold: CNC center can also be used to manufacture various molds, such as plastic molds, casting molds, die-casting molds, etc.

- the application industry of the manufactured product

CNC machine tools have a wide range of applications in different industries, making them the machines of choice for different kinds of industries.

- Automobiles and Transportation

Automobile: For parts of buses, cars, motorcycles, trucks, CNC can automate the production of these parts.

Trains: Can cut and shape the strong exterior parts of trains.

Aerospace: Some exterior and interior components of aircraft and spacecraft are the product of CNC machines.

Nautical: Exterior and interior components of many boat models come from CNC.

- Original Equipment Manufacturer

OEMs use CNC machines in the metalworking process to produce a variety of components and product designs.

Prototyping: CNC has 3D and 2D capabilities to make prototypes for parts and finished products.

Mass production of parts: CNC machine tools are controlled by computer programs and can automatically produce some parts.

- Consumer electronics and other products

For electronics and other consumer goods, high precision in the production process is a must.

Electronic Components: Machine cuts sensitive metal parts in special shapes to make electronic functions more powerful.

Shell: CNC can also make the shell.

Appliance Components: The heavy-duty parts that make up reliable home appliances.

Working with metals, plastics, and many other materials, CNC machines facilitate multiple steps in consumer manufacturing.

- Construction and building materials

Construction elements: wood and metal can be CNC.

Pipes and railings: bending of metal pipes and pipes for construction works.

Architectural Models: CNCs are also best at producing detailed structural models in plastic and composite materials during the architectural design process.

Aixi has many years of experience in manufacturing and exporting precision parts. Our products are widely used in sports equipment, medical treatment, security equipment, industrial manufacturing, automobile manufacturing, electronic products, metal products and other fields. CNC machines are one of our key partners in advanced manufacturing, making our work more efficient.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español