All post-processing adds to part production costs and production time, but the right surface finish can go a long way toward making the original design vision a reality. Metal surface treatments for CNC machined parts typically include various mechanical processes such as tumbling, brushing, and sandblasting, but metal parts can also have chemical surface treatments…

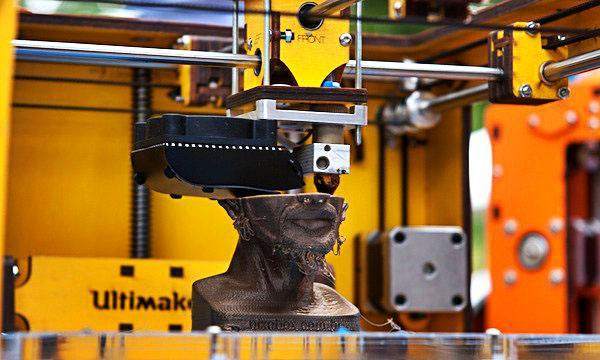

3D printing, also known as additive manufacturing, covers several distinct 3D printing processes, but the key processes of these technologies are the same. 3D printing all starts with a digital model because the technology is digital in nature. A part or product is initially designed using computer-aided design (CAD) software or an electronic file obtained…

CNC machining is a method of machining using computer-controlled CNC machine tools. It generates instructions through pre-written processing programs to control the machine tool to cut along the specified path, thereby realizing the processing of the workpiece. CNC machining can be performed on almost any material from expanded polyurethane foam to nickel superalloys. CNC machining…

AIXI wishes everyone a happy Halloween Happy Halloween Happy Halloween Happy Halloween Happy Halloween Happy Halloween Happy Halloween Happy Halloween Happy Halloween Happy Halloween happy Halloween happy Halloween happy Halloween

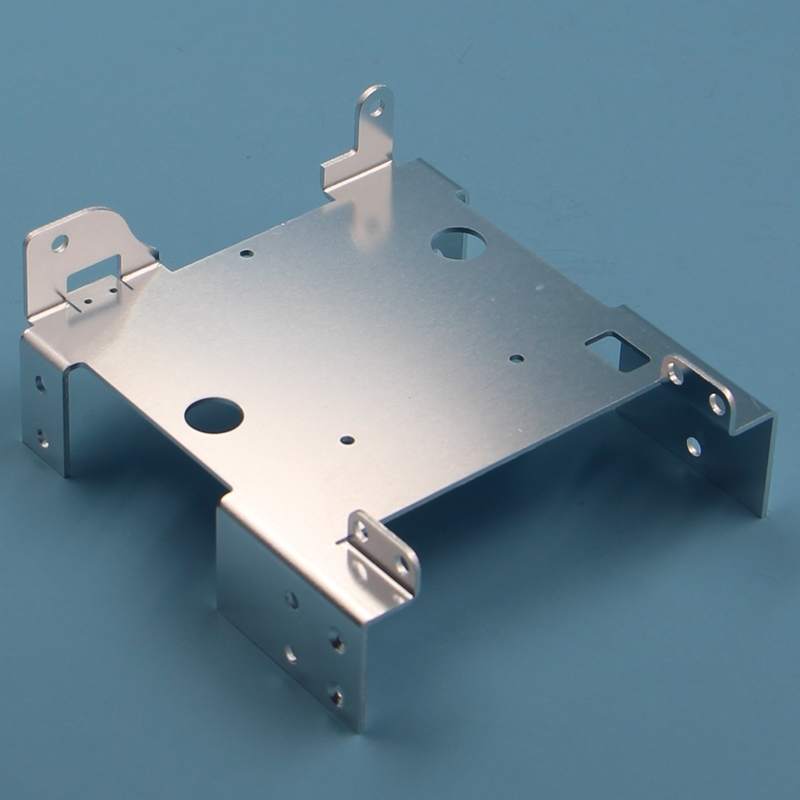

Sheet metal is a comprehensive cold working process for metal sheets usually less than 6mm, including shearing, punching, cutting, compounding, folding, riveting, splicing, forming (such as automobile bodies), etc. Sheet metal processing is called sheet metal processing. For example, plates are used to make chimneys, iron barrels, fuel tanks, ventilation ducts, elbows, large and small…

The automotive industry is constantly facing challenges – there is an urgent need to adopt more environmentally friendly production methods to promote sustainable development. Traditional manufacturing techniques such as casting, forming and machining have a significant impact on the environment. In response, the automotive industry is aware of this challenge and has begun adopting sustainable…

CNC copper machining is one of the most precise metal machining services for manufacturing copper parts across industries. Copper has ductility, high thermal and electrical conductivity, corrosion resistance and wear resistance, good formability during hot and cold working, and is a good conductor of heat and electricity. These properties make it the right choice for…

Acrylic and polycarbonate are very similar in many ways, but there are some important differences. So we often choose the best material based on factors such as lead time and cost, ease of processing, and the specific application for which the material is suitable. Characteristics of Acrylic and Polycarbonate characteristic acrylic acid polycarbonate Strength and…

MJF (Multi Jet Fusion) is an additive manufacturing technology developed by HP Inc. It is a 3D printing process that can produce functional nylon prototypes and end-use production parts in 1 day and involves layering Powdered thermoplastic materials to quickly create complex parts. The final part has a high-quality surface finish, excellent feature resolution, and…

As AIXI Hardware, We have moved from Shenzhen to the great manufacturing city of Dongguan in September. Due to the high rent in Shenzhen, we always reduce our profits to provide customers with better prices, which is limited by our development. Therefore, after a long internal discussion, we decided to move the factory to Dongguan….

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español