As we all know, the reason why the processing of precision parts is called precision machining is precisely because its processing procedures and processes are very demanding, and the precision of the products is very high. The precision of the processing of precision parts includes the accuracy of the position The accuracy of dimensions, the…

The five-axis linkage machining center is a high-tech and high-precision machine tool specially used for processing complex curved surfaces. This machine tool system is suitable for a country’s aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment and other industries. Has a decisive influence. Five-axis linkage means that there are at least five coordinate…

The copper parts in the general household socket can ensure the smooth current and reduce the heat-hazard components. Thick copper sheet, improve current passing ability, reduce the resistance of copper parts; anti-oxidation, no rust, reduce the increase of resistance due to rust and heat generation; less riveting, preferably a whole piece of copper, further reduce…

Nowadays, bending pipe processing technology has spread to all walks of life, such as the now very hot automobile industry and aerospace industry, etc., all kinds of bending pipe products are often used. For these industries, the quality of bent pipe processing products will directly affect the structural rationality, safety and reliability of the products…

Elbow processing is very common, and different industries have different uses. Many people know elbows. However, they often do not have a comprehensive understanding of the applications of elbow processing. A variety of elbows are used in some pipelines, such as vessel pipelines, car fuel pipelines and other pipelines. Compared with other types of elbows,…

Pipe bending should be made with pipes with a positive wall thickness. The bending radius of the high-pressure steel pipe should be more than 5 times of the outer diameter, and the bending radius of other pipes should be 35 times larger than the outer diameter of the pipe; when the pipe is made of…

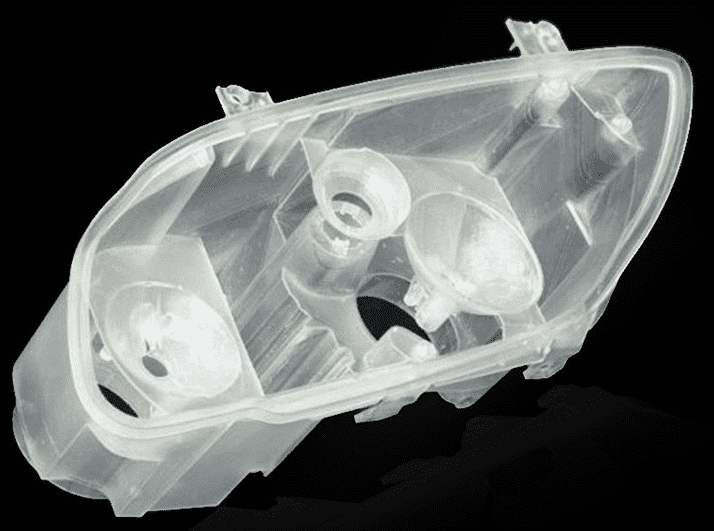

With the recent acceleration of industrial upgrading in various industries, 3D printing technology has made progress, and R & D personnel have gradually become accustomed to using 3D printers in projects that produce transparent objects. The transparency of product materials is pursued in many industry applications: from the production of lenses for optical engineering or…

If you want an effective transparent 3D printing model, what is the most critical point? Of course, it is the choice of materials. After all, the materials that can be used in the 3D printing model are those. Some are white and some are yellow. If you need a color effect, you can paint later,…

1. Common classification: Brass is an alloy composed of copper and zinc. White copper is an alloy of copper and nickel. Bronze is an alloy formed of copper and elements other than zinc and nickel. There are mainly tin bronze, aluminum bronze and other copper. Copper content Very high copper, The total content of other…

As a processing technology, plastic mold processing, after its production or completion, will be somewhat defective. How to solve this situation? 1. Dent. The causes of dents are: 1) Insufficient cooling of the mold, insufficient cooling time will cause serious deformation. 2) This situation also occurs when the internal pressure of the mold is insufficient….

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español