In the process of aluminum alloy gravity casting, as the shape of its castings is different, the casting molds of its products are also different. Even if it is the same part, the mold form is often different with different casting processes, but in any case Aluminum alloy gravity casting molds still have their commonalities….

Aluminum alloy processing methods can be divided into two categories: deformed aluminum alloys and cast aluminum alloys: Deformed aluminum alloy can withstand pressure processing. It can be processed into various shapes and specifications of aluminum alloy materials. Mainly used for manufacturing aviation equipment, doors and windows for construction, etc. Deformable aluminum alloys are divided into…

The main types and characteristics of gear transmission Gear transmission: Gear transmission is achieved by driving the driven gear in turn to drive the driven gear. One of its basic requirements is that the ratio of its instantaneous angular velocity must remain unchanged. Classification of gear transmission: There are many types of gear transmission. According…

Gear and rack drive position accuracy The precision of gear rack transmission position is generally less than 0.1mm. Rack and pinion drive Advantages: Large bearing capacity, high gear and rack transmission accuracy, up to 0.1mm, can be continued with unlimited length, transmission speed can be very high,> 2m / s Disadvantages: poor processing and installation…

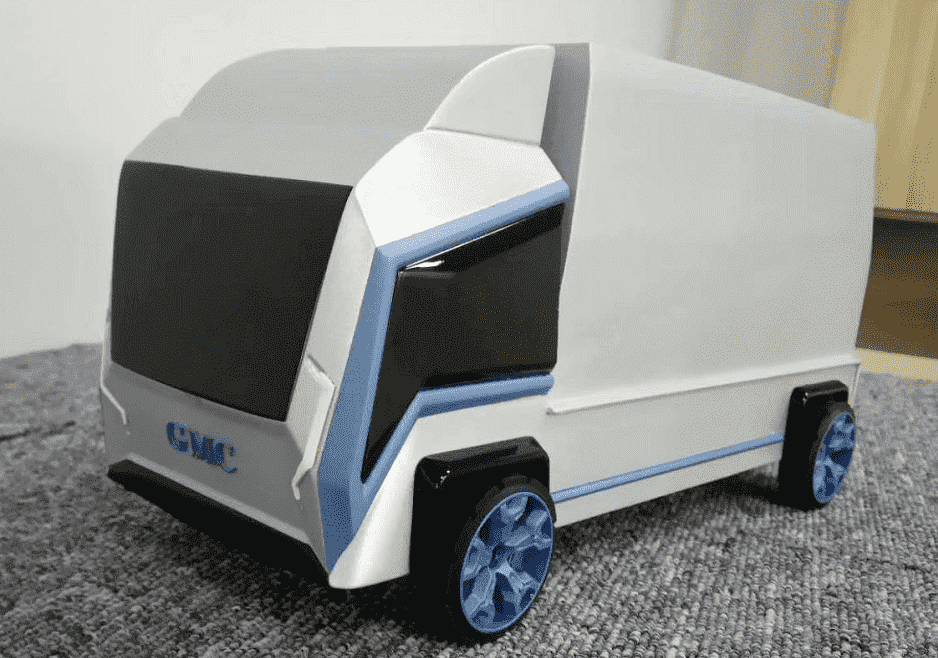

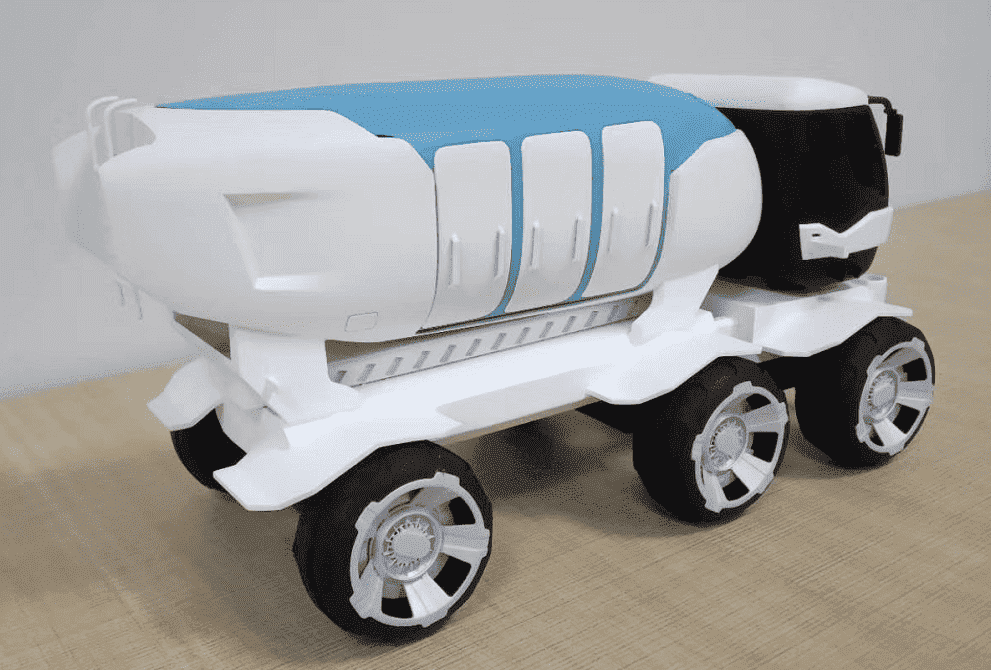

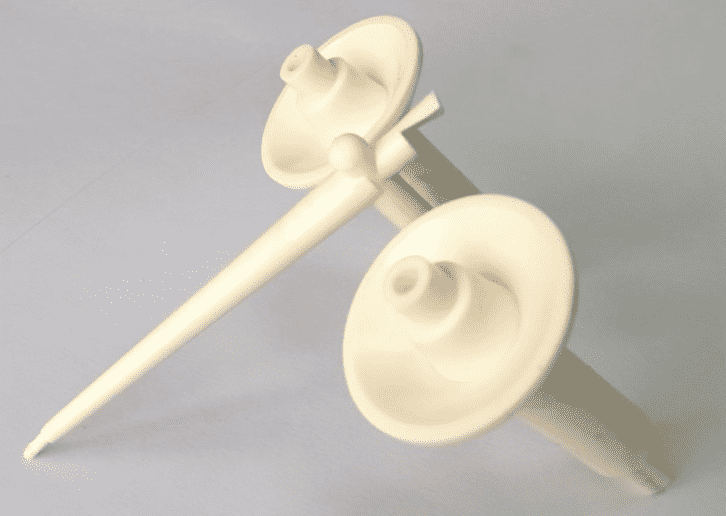

3D printing is becoming more and more popular. 3D printing prototypes, 3D printing manuals, 3D printing education, 3D printing medical devices, 3D printing parts, or small things you design yourself, you can quickly print one through 3D printing. The model comes. Many people asked, how much does it cost to 3D print a model? Is…

3D printing is also called rapid prototyping technology. It is a technology based on digital model files (3D stereograms), which uses plastic materials such as resins and powdery metals and other adhesive materials to construct objects by layer-by-layer printing. Since the advent of the 3D printing prototype, it has highlighted its advantages in industrial manufacturing…

By using the right combination of equipment and software, the efficiency is significantly improved. The automation system has the obvious advantage of increasing productivity, as much as two-thirds in some applications, while providing a more precise method to maintain inventory during this process In the meantime, they improve operational efficiency and productivity, reduce inventory levels,…

The design of injection molded parts generally requires the design of the number and arrangement of mold cavities. The cavity of the mold cannot simply apply the dimensional tolerance of the mechanical parts. The dimensional accuracy of the plastic parts will be affected by many factors such as the structure of the plastic parts, the…

Whether a set of injection molds are successfully opened depends mainly on whether the injection molds have a lot of problems? A successful set of molds can be reflected in product appearance, assembly, and production efficiency. Then, relatively speaking, the more injection mold molding problems, the greater the possibility that the mold is not opened…

As an injection mold technician, do you know these 18 knowledges? 01 Shot Tsui The melt usually flows from the nozzle into the nozzle, but in some molds, the nozzle is part of the mold because it extends to the bottom of the mold. There are also two main types of nozzles: open type nozzles…

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español