What Is Anodized Aluminum?

If you’re wondering, “What is anodized aluminum?” you’re not alone. The term has been used in many contexts. In this article, we’ll explore the meaning of this word. This unique process produces the beautiful, hard-wearing surface of many aluminum products. In a nutshell, anodized aluminum is a protective coating applied to aluminum. The process involves the application of a barrier layer to protect aluminum from further chemical reactions.

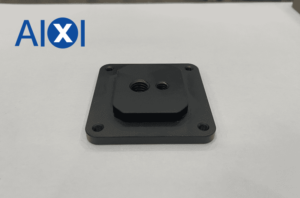

Anodized aluminum is treated using a chemical bath made of chromic or sulfuric acid. This chemical solution results in a uniform, a corrosion-resistant layer that is more durable than its untreated counterpart. In addition to aluminum, titanium and magnesium can also be anodized. The process also polishes the metal, which shields it from scratches. Some types of anodized aluminum can have special visual effects. Thick anodized aluminum can absorb colors, while thin anodized aluminum has a translucent layer.

What Is Anodizing?

Anodizing is a process that increases the natural oxide layer of a metal’s surface. It’s a common procedure used on aluminum and other metals, such as copper, to increase their resistance to corrosion. Here are some of the benefits of anodizing. They’ll help you make better decisions about the metal in your home or business. Read on to learn more. If you’re interested in learning more about anodizing, keep reading.

One of the major benefits of anodizing aluminum is its aesthetic appeal and durability. When aluminum is exposed to oxidation, it reacts with oxygen and other chemicals, leading to rust. Anodizing aluminum can increase the lifetime of your product by as much as 300%, and it’s widely used. The process begins with cleaning the aluminum and putting it into an electrolytic solution primarily composed of sulfuric and chromic acid. These acids react with the aluminum surface to create a protective barrier.

Benefits Of Anodizing Aluminum?

Anodized aluminum has a number of advantages over raw aluminum. The resulting coating is three times harder than raw aluminum, and it operates at any speed. Its benefits include corrosion resistance, durability, and outstanding beauty. Anodized aluminum can be used in a variety of products, including consumer goods and aircraft interiors. It also can be colored in any color you want. For more information, read on to learn about the benefits of anodizing aluminum.

Anodizing changes the surface of aluminum so that the resulting coating is one of the hardest materials available. Aluminum has an oxidized layer, which can corrode with water and chemicals. Anodized aluminum has a higher level of oxidation, making it resistant to abrasion and corrosion. Anodized aluminum is also highly resistant to scratching and other forms of damage. A wide variety of applications make anodized aluminum a practical choice.

Final Thoughts

Additionally, anodized aluminum offers the same visual effect as heavier metals, so you can use it anywhere. Its unique qualities are what make it a popular choice for outdoor and interior applications. It is also environmentally friendly, requiring little maintenance and offering exceptional durability. Finally, anodized aluminum is lightweight, durable, and attractive.

Anodized aluminum is also recommended for coating by many manufacturers. This finish is incredibly durable and will extend the life of your aluminum. Powder coating, paint, and epoxy are all popular options for completing this process. However, they can be expensive and difficult to apply evenly.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español