Surface treatment technology and function of CNC machining (lathe, CNC milling machine) parts, cost of surface finish

For each product, specific surface treatments are available for CNC machined parts. However, the surface finish of the product tends to add a corresponding cost.

Some finishes, such as high polish, are designed to remove any marks from the machining process.

Surface treatments can produce reflective surfaces.

Matte finish or sandblasted to eliminate reflections.

Mirror finish on clear plastic looks like glass.

Finishing paint and staining may change the color of the product.

Laser engraving can decorate your products.

With laser printing, you can print letters or patterns on the product after it is finished.

Soft finishing involves applying a soft rubber-like coating to the product.

Some surface treatments play an important role in making your product last longer. These include galvanized, anodized and brushed.

What is CNC machined surface finish and precision machining ?

CNC machining surface finish can be divided into:

oxidation treatment,

paint processing,

plating,

polishing,

brushed,

sandblast,

fuel injection,

silk print

silkscreen,

plating,

UV

Metal corrosion processing

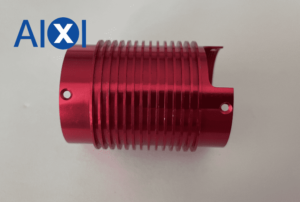

1. Oxidation processing: The price of CNC processing When producing CNC processed finished parts (mainly aluminum CNC processed parts), the oxidation process is used to harden the surface of CNC processed products and not easy to wear.

2. Painting processing: painting processing is used in the production of CNC precision machining parts. Spray paint treatment to prevent rusting of CNC machined parts, such as daily necessities, electrical cabinets, handicrafts, etc.

3. Electroplating: Electroplating is also the most commonly used processing technology for CNC machining parts. The surface of the CNC machined parts is galvanized with modern technology to ensure that it will not mold or fall off after prolonged use. Electroplating standard processing includes screws, stamping parts, batteries, auto parts, small parts, etc.

4. Polishing: Use polishing materials for polishing, wax polishing, copper water rubbing, etc., manual polishing. Clean the sharp corners on the smooth surface to avoid harm to the human body during use.

5. Brushing: draw some strokes on the surface of aluminum or steel parts or other products to make the sample feel better. Plastic wire drawing is usually sprayed with a thick layer of paint, and then processed by this process. The effect is worse than that of metal CNC aluminum machining parts. The texture is worse than metal parts.

6. Sandblasting: There is a lot of plastic remaining in the CNC sample, and manual operation is very difficult, especially when there are many holes or buttons, it is very time-consuming.

So use a sandblaster. Residual plastic falls off. Aluminum CNC machined parts or other metal parts are tool lines that can cover the surface. Some customers also request sandblasting, followed by oxidation, to give the body a solid granular metallic feel.

7. Paint spraying: According to customer requirements, the products we produce are fueled. Our site is a dust-free oil filling room, using the best oils. (Can be sprayed with rubber oil, bright varnish, light semi-matte, matte, baking paint and different paint colors)

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español