La adaptabilidad de la máquina al CNC ha supuesto revoluciones en el proceso de fabricación. Estas máquinas han hecho que el trabajo en metal sea más fácil y rápido. Existen diferentes tipos de máquinas CNC. Comprender las aplicaciones del mecanizado CNC puede abrir puertas a nuevas eficiencias. Curiosamente, el uso de máquinas CNC se ha…

Archivos de Categoría: Mecanizado CNC

La máquina CNC ha revolucionado el trabajo del metal. El proceso de fabricación solía llevar días y ahora se completa en minutos. Existen diferentes máquinas basadas en CNC que ayudan a los fabricantes. Sin embargo, las máquinas CNC de 3 ejes frente a las de 5 ejes han sido un tema candente de discusión. Ambos…

Introducción El mecanizado CNC ya ha ganado la carrera debido a su alta precisión. Ya sea que utilice plástico o materiales sólidos, esta fabricación sustractiva elimina márgenes innecesarios y produce un material perfecto. Uno de los materiales más populares es PEEK, un polímero termoplástico. Ofrece excelentes aplicaciones debido a su elegante resistencia a la…

Introducción Caminar por el imperio de los sectores industriales te permitirá descubrir datos sorprendentes. Cientos de máquinas trabajan bajo un mismo sistema de control y producen continuamente productos de calidad. Esta exactitud en las precisiones se arrodilla ante las máquinas CNC, que han estado invictas durante décadas.Con el tiempo, el mecanizado CNC ha proporcionado…

El mecanizado por control numérico por computadora (CNC) es un proceso crucial en la fabricación, que permite cortar y dar forma con precisión a diversos materiales. El éxito de cualquier proyecto de mecanizado CNC depende en gran medida de la elección del material. La selección del material adecuado garantiza la funcionalidad, durabilidad y rentabilidad deseadas…

El servicio de corte CNC se refiere a la instrucción (o programa) de la pieza de trabajo utilizada para controlar máquinas herramienta o equipos, que es un nuevo método de control proporcionado en forma digital. Cuando se proporcionan instrucciones al dispositivo de control de la máquina cortadora automática CNC, la máquina cortadora puede cortar automáticamente…

Classification, characteristics, functions and usage precautions of cutting oil in machining Mechanical cutting oil is a special lubricating oil. It is mainly used for lubrication, cooling, cleaning, anti-corrosion and other functions during metal cutting. It can improve cutting quality, extend the life of cutting tools, improve production efficiency and reduce costs. . Correct selection and…

CNC machining is a method of machining using computer-controlled CNC machine tools. It generates instructions through pre-written processing programs to control the machine tool to cut along the specified path, thereby realizing the processing of the workpiece. CNC machining can be performed on almost any material from expanded polyurethane foam to nickel superalloys. CNC machining…

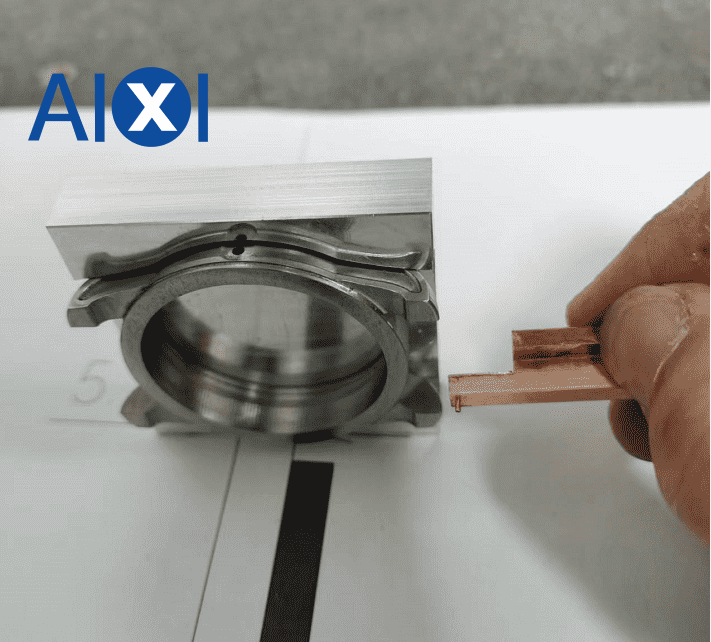

CNC copper machining is one of the most precise metal machining services for manufacturing copper parts across industries. Copper has ductility, high thermal and electrical conductivity, corrosion resistance and wear resistance, good formability during hot and cold working, and is a good conductor of heat and electricity. These properties make it the right choice for…

Acrylic and polycarbonate are very similar in many ways, but there are some important differences. So we often choose the best material based on factors such as lead time and cost, ease of processing, and the specific application for which the material is suitable. Characteristics of Acrylic and Polycarbonate characteristic acrylic acid polycarbonate Strength and…

English

English Deutsch

Deutsch Français

Français 日本語

日本語