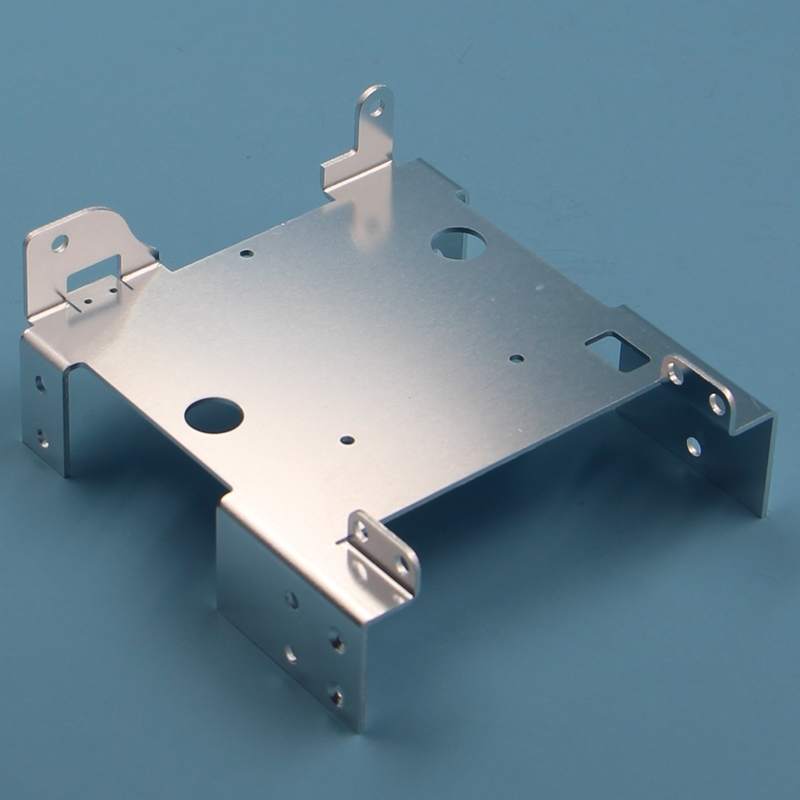

Sheet metal is a processing technology, a comprehensive cold processing technology for metal sheets (usually less than 6mm), including shearing, punching, cutting, compounding, folding, riveting, splicing, forming (such as automobile bodies), etc. Its distinctive feature is that the thickness of the same part is consistent. Common sheet metal manufacturing processes include cutting, welding, forming, bending, connecting, etc. The choice of process depends on the specific requirements of the application. Forming and cutting are often necessary steps in the manufacturing of aluminum sheet metal.

Sheet metal process characteristics

Sheet metal has the characteristics of light weight, high strength, conductivity (can be used for electromagnetic shielding), low cost, and good mass production performance. It has been widely used in electronic appliances, communications, automotive industry, medical equipment and other fields, such as in Sheet metal is an essential component in computer cases, mobile phones, and MP3 players. As the application of sheet metal becomes more and more widespread, the design of sheet metal parts has become a very important part of the product development process. Mechanical engineers must master the design skills of sheet metal parts so that the designed sheet metal meets the requirements of the product. Requirements such as function and appearance can make the manufacturing of stamping molds simple and low-cost.

Advantages of aluminum plate processing

Aluminum sheet parts can be used in place of heavy-duty materials to reduce weight.

Aluminum has high resistance to corrosion, heat, rust, wear and tear.

Aluminum is a low-cost option for sheet metal fabrication projects.

Aluminum sheets can be cut, bent, stretched or rolled into almost any shape.

Aluminum parts retain their shape for years.

Types of metal aluminum commonly used in sheet metal manufacturing

Aluminum 6061 (T6): A heat-treated structural aluminum alloy suitable for aerospace applications. Aluminum 6061-T651 is the primary choice. It has poor formability and weldability compared to other grades. 6061 aluminum machined parts are commonly used in ships, auto parts, bicycles, etc.

Aluminum 5052 (H32): Although 5052 aluminum plate is much stronger than 6061, it retains its weldability, corrosion resistance, and formability, making it ideal for applications such as storage tanks or chassis.

Aluminum 1100 (H14): Most ductile for welding and deep drawing, but lowest strength. It is economical, pure and highly adaptable to chemicals and weather, making it the first choice for chemical processing applications.

Aluminum 3003 (H14): Stronger than 1100 grade aluminum, 3003 is still ductile, cheap, weldable, and corrosion resistant. It is often used in storage solutions such as cabinets or tanks and is ideal for stamping and drawing.

AIXI As an experienced metal processing and fabrication company, we are experts in manufacturing a variety of custom aluminum products, including sheet metal parts and assemblies suitable for specific applications. Whether you need accessories or parts for car doors, medical equipment, digital devices and customer products, our aluminum sheet metal manufacturing services can provide you with high-quality aluminum sheet metal parts with significant advantages. AIXI has been a fast-growing, reliable online manufacturer and supplier of, in addition to metal fabrication, other services and processes that handle metals and plastics at our factory.

Reasons to choose AIXI aluminum sheet metal processing

Skilled and capable engineers, technicians and operators

Customers will be promptly informed of every progress throughout the cycle

Provide accurate dimensions and specifications as per customer requirements

Custom aluminum parts range from regular machine parts to complex shapes

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español