3D printing technology has been in use since the 1980s. Its inception made the creation of 3D objects a lot easier. With the technological revolution, 3D printing has become better and more efficient. From small entities to large production, this technology handles everything smoothly. Many different technologies are used in 3D printing to get the desired outfit. Each of those works differently and gives varying results. In this article, I will shed light on various types of 3D printing technologies. So, let’s get started!

Overview of 3D Printing

3D printing technology is an additive process that builds 3D objects layer by layer. It uses digital designs as input and works on it. It is cost-effective, efficient, and the quickest way to produce large goods. Many industries and businesses use this technology for prototyping.

Unlike CNC machining, this technology creates objects by adding layers instead of cutting. The work of 3D printing is straightforward. First, the designers make the designs using different software or CAD. After that, the design is sliced using another software. Once the slicing is done, the design goes to the printer.

It creates the final products in layers. What makes this technology famous is its inexpensiveness. It can efficiently work with different materials. Those include metals, plastics, resins, and ceramics. 3D printing technology is booming in aerospace, automobiles, healthcare, construction, etc.

8 Different Types of 3D Printing

3D printing is very versatile. The engineer uses different 3D techniques to get desired product shapes. However, a few main types are most used across various industries. All of these types give varying final outputs based on users’ requirements.

They differ in terms of input material, shapes, and cost. However, they are all additive manufacturing processes. It means they build shapes, not by cutting or removing the material. Let’s dive in and discuss the types in detail.

1- Stereolithography (SLA)

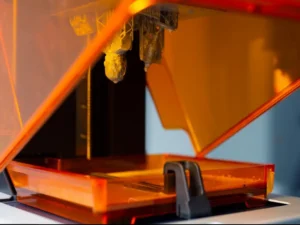

This printing technology is suitable when smoothing finishing is required. It uses liquid photopolymer resin as the starting material and UV laser beam. The printer’s tank carries this resin. The laser point directs the laser beams into the liquid. The computer controls this process.

The laser beams move in the X and Y axes. The movement of the beam creates a layer. The whole product is made in the layers. The laser beam keeps moving in axes to create the product. In this way, the users get a physical object in the form of a digital design.

Notably, it is the oldest and classic way of 3D printing. The engineers use it for both precision and quick turnaround. As this type of 3D printer is not expensive, it is also used for prototyping. The samples or designs are made in physical shape for testing, etc.

2- Selective Laser Sintering (SLS)

This printing technology also uses a laser that melts the material. The material is used as powders, typically nylon or thermoplastics. The lasers usually have a high temperature that easily sinters the powder particles (material).

Notably, SLS 3D printers consist of powder beds containing material in the form of particles. The digital design is fed to the printer. The laser starts working by melting and fusing the powder particles in the powder bed.

The place where laser strikes changes into a solid due to particular fusions. They keep moving in the X and Y axes and make the powder into a solid form. In this way, the laser creates a design using layers according to the computer’s instructions. This method can easily create very complex shapes.

3- Fused Deposition Modeling (FDM)

This type of 3D printing technology consists of extruding filament. Typically, the thermoplastic (hard or soft form) is used as the filament. This filament goes through the heat and melts. Once it melts, it goes into the semi-liquid form.

The filament goes above the subject and starts making layers. The semi-liquid filament cools when it comes out and makes a solid shape. Remember, the extruding filament also creates physical parts by making layers. The computer also controls this process of printing.

This process is less expensive and easy to use. Infact, it is trendy among hobbyists and prototypers. However, the parts or shapes made through this printing method lack strength. Their durability could be better. However, people still use it due to its cost-effectiveness.

4- Digital Light Processing (DLP)

This DLP printing method is similar to Stereolithography. However, it uses a digital light projector screen instead of a laser source. The remaining steps are identical in these two types of 3D printing. Both use photopolymer resin as a starting material.

The light from the light source interacts with the resin. The part of the resin where light touches changes into the solid. In this way, the light projector makes shapes in layers. Remember that the light projector screen cures all the resin layers simultaneously.

This means that the process of DLP is much faster than that of SLA. Thanks to the collective curing of all the layers. Not only is this method quick, but it is also cost-effective as well. Engineers use this type of printing to produce health-related products such as implants, etc.

Point to Remember: The DLP method offers better finishing and resolution than SLA. Its usage is getting more famous. It is believed that it will replace SLA to a large extent.

5- PolyJet

It is premium and high-end 3D printing technology. Its functionality is more like inkjet printers. Just like other methods, we use photopolymer resin as the material. However, it is treated differently. First, the tiny droplets of resin are sprayed on the dish or tray.

The ultraviolet light is then put on this tray, which has a droplet of photopolymer resin. The drops where UV light strikes solidify. Thanks to the sensitivity of the resin against the light. The engineer continuously cures the resin layer by layer and gets the final product.

This method can be effective in getting designs with different colors. It can even provide material with multiple color gradients and transparencies. However, this process is super expensive. If you need one color shape, I recommend you go with SLA.

6- Multi Jet Fusion (MJF)

To some extent, this method of 3D printing is similar to the selective laser sintering type. However, it does not use any laser source. Unlike SLS, the heat does not fuse nylon particles. This method works in different ways as it uses the combining agent.

First of all, the nylon drops are sprayed onto the build plate. Then, the primer nozzle feeds the combining agents on this build plate. This agent is not put in bulk but instead sprayed. It does not fuse with the nylon powder.

These nylon powders and the fusing agent go through the heat. Due to high temperature, the nylon drops combine with agents and make products in layers. This method offers excellent precision. Unlike the SLS, it also works to provide different colors. However, it is slightly more expensive, which significantly limits its usability.

7- Direct Metal Laser Sintering (DMLS)

This method is similar to SLS but uses metal powder instead of plastics or nylon. The material (metal powder) is placed on the build plate. The laser source is used to sinter the powder particles. The lasers fuse the powders and make solid shapes.

It is interesting to note that this method is slower. The reason is that the lasers must repeatedly sinter the powder in each layer. However, this method of 3D printing offers ideal strength and durability. Engineers use this method to produce metal parts in very complex shapes.

8- Electron Beam Melting (EBM)

In this type, the electron beam acts as the heating source. The starting material, powder, is sprayed on the plate. The electron beam is then bombarded on this plate. The dedicated computer system controls this electron beam.

The bombardment of an electron beam works selectively. It melts and fuses the powder material and creates 3D objects layer by layer. This whole process works in a vacuum. What makes this method stand out is its speed.

The electron beam melts many places or particles at once. In this way, the fusing in different layers is completed quickly. The resultant product is also of high strength. The reason is that high-energy lasers fuse particles and make homogeneous microstructure.

Which 3D Printing Type to Use?

Well, there is no definite answer to this question. The type you should use depends on many factors. If you are a small business, your needs will differ from those of a more stable business. Before choosing, you should look at the following aspects:

- Budget & affordability

- Type of Starting Material

- Geometry of the object

- Strength of the Object

- Turnaround and Colors Schemes

All these factors have an impact when it comes to choosing a specific 3D typing. Usually, fused deposition modeling (FDM) is considered suitable for masses. If you work on a lower scale, this type would be cost-effective.

However, going with EBM will make sense if you want more color schemes and product strength. Remember that no one can tell you to choose any specific type. You’ll have to analyze your needs and requirements to decide on a particular type.

Frequently Asked Questions

What is the best type of 3D printing for beginners?

For beginners just starting, fused deposition modeling is a suitable option. It is affordable and offers optimal value. This type is helpful for someone planning to run a 3D printing business.

Are material extrusion and FDM fast and cost-efficient?

Yes, generally, this method offers quick turnaround and affordable pricing. However, the speed of this printing usually depends on the type of material you are using. So, their work speed can vary depending on the material.

What is the most common type of 3D printing?

Electron Beam Melting and Fused Deposition Modeling are well-known in different industries. Electron beam melting is relatively very expensive. So, FDM is what people consider for their work.

I want something colorful with different gradients. Which type will suit my task?

Both polyJet and Multi Jet Fusion are excellent options if you need colors. However, these types are costly to use. They can produce gradients, transparencies, and other effects in colors and different colors. However, you must have a handsome budget.

Conclusion

Each of the 3D printer types varies in functionality. However, one thing is common – they work from layer to layer. They produce excellent 3D products from digital design. What kind you should use depends on the result you want.

Fused Deposition Modeling is the way to find a cost-effective solution. If budget is not a concern, going with EBM or MJF would be ideal. I have all the ins and outs of these 3D printing technologies in this guide.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español