Can Pom Be Machined?

Whether you’re wondering “Can pom be machined?” or “what machines are available for machining poms” depends on your needs. CNC machining is the preferred option when poms must be produced quickly and accurately. CNC machining uses tools that can be reused and reusable, whereas injection molding requires a new mold for every part, which can be expensive and time-consuming. CNC machining can be performed on aluminum, brass, or steel. However, this process is prone to risks, including injury to the machinist.

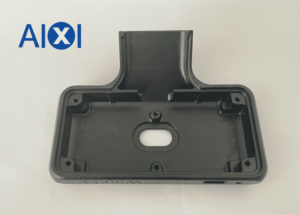

CNC Machining POM Parts

CNC machining POM parts can produce many high-quality pieces. These recyclable parts are perfect for a number of industrial and commercial applications. For example, POM is often used in medical devices, such as implants and bone plates. The polymer has excellent strength, stiffness, and wear resistance. It can be sterilized, so it won’t react with other substances during surgery. Plastic parts are also a popular choice in the electronics industry. CNC machining POM parts creates a durable, strong piece of plastic.

Applications For Pom Machining

Despite its name, pom machining is not new. It involves the process of molding a polymer into a specific shape or size. This method involves the use of pressure and heat to form a strong, durable piece. Some of the most common applications for POM include engine valves, sliding elements, guiding elements, connectors, cogwheels, and some medical equipment. However, if you’re considering using this process for your own project, make sure to follow safety procedures.

Process Of Machining Pom Parts

There are two general ways of machining POM parts. The first is through conventional machining techniques. These methods can produce POM parts of different sizes. The largest POM parts are usually around 4″ or 5″ in diameter, but smaller ones can also be made. While these large poms are more costly to make, they are also more stable than their smaller counterparts. The second method is to anneal a pre-machined POM part.

Machines Used For Pom Machining

Many machining industries use POM to manufacture a variety of items, including mechanical gears, connector elements, sliding and guiding elements, cogwheels, and more. Machines for pom machining are also used for medical equipment. While POM is an environmentally friendly material, if improperly shaped or machined, it can cause deformation and other problems. For this reason, safety is a major consideration when working with POM.

Other Engineering Thermoplastics That Can Be Machinable

Among other engineering thermoplastics that can be machined, PEEK is a superior choice due to its unusual combination of mechanical properties. The material is extremely resistant to wear, creep, and chemicals, and is highly machinable. Another thermoplastic material with outstanding machinability and machineability is PEEK, a high-performance alternative to fluoropolymers. It is biocompatible and recyclable, making it a versatile material for a variety of industries.

CNC Machining PP, Teflon, and Delrin

When choosing a material for CNC machining, POM, Teflon, and Delrin are all good options. These materials are similar in properties but differ in their machining qualities and applications. If you’re unsure which material is best for your application, you can feel the difference by touching them with your fingers. Both materials are easily machinable and have different properties. You can learn more about them in this article.

CNC Machining Pom

CNC machining PP requires careful consideration of several factors. The material’s toughness and fatigue resistance make it a good candidate for CNC machining, but the high degree of heat and pressure can be detrimental to the material’s overall strength. This material also has variable thermal expansion and tends to gall. This makes it a difficult material to machine, especially if you need to produce flexible parts that will be exposed to harsh environments.

A CNC machinist can use Delrin pom to machine a variety of parts. The semi-crystalline nature of Delrin makes it an excellent material for machining. This makes it easier to work with than some other materials. Several other benefits make Delrin pom ideal for CNC machining. Here are just a few. Read on to find out more about this material and how it can benefit your CNC machining needs.

HONY(r)POM is a linear polymer with no side chains, but with excellent mechanical properties. Its high mechanical strength and low shrinkage properties make it a good material for gear and bearing applications. The material also has a high level of rigidity and low coefficient of friction. HONY(r)POM is also known as Saigang, and is an engineering plastic with outstanding thermal and wear resistance.

CNC machining HDPE plastic offers many benefits over traditional methods. This durable, slippery plastic has excellent chemical and electrical resistance, and is ideal for low-friction applications. The materials are easily machinable, but the minimum diameter of tools and drill bits is usually around 12x the diameter of the material. Here are some examples of applications where HDPE is an ideal choice. CNC machines can also be used to create deep pockets with small radii.

PP-H CP CNC machining of POM parts has several advantages over its counterpart. This material exhibits low coefficient of friction, good wear resistance, and dimensional stability. It is also an excellent alternative to metals due to its dimensional stability, low moisture absorption, and low friction. Compared with steel, POM has excellent machineability and polishing properties, and is ideal for mechanical components.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español