Is Aluminum A Common Prototyping Material?

If you’re a product designer, you’re probably wondering, “Is aluminum a common prototyping material?” If so, you’re not alone! Aluminum is often used for prototype manufacturing due to its outstanding qualities, including corrosion resistance and strength. This makes it a highly suitable choice for various projects, from pre-production prototypes to functional and hybrid models. Here are some ways to use aluminum for prototyping.

In the first-to-market environment, aluminum extrusion prototyping is an excellent solution. The fast production time allows for high-performance standards for components and functional analysis. Prototype aluminum is an ideal choice for a variety of applications, including automotive parts, medical devices, and aerospace systems. However, there are certain aspects of aluminum that you should be aware of. If you’re unsure of whether aluminum is the right choice for your project, it’s important to contact a professional aluminum prototype manufacturer.

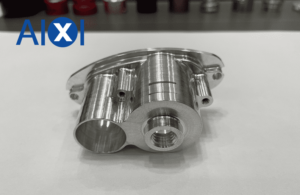

Premium aluminum prototyping manufacturers use futuristic machinery and follow a quality-based manufacturing process. They start by creating a CAD file from the customer’s idea. The CAD file learns all the features required for the product. Next, it’s fed into a CAM (Computer-Aided Manufacturing) system. CNC machinery then produces the finished product. Aluminum is an excellent material for prototype manufacturing.

Prototypes made from aluminum are cheaper than hardened steel and can be created faster. In addition, aluminum is less expensive than injection molds and carbon fiber. Many aerospace and defense industries use aluminum in their production processes, while the automotive industry relies on its machining capabilities. It can also be used in a wide range of applications, including medical devices and aircraft parts. However, aluminum is not suitable for high-finish applications.

When it comes to prototyping, CNC machining is an excellent choice for the aluminum industry. Not only does it create parts with high accuracy and precision, but it’s also a cost-effective way to produce large quantities of small parts. CNC aluminum prototyping has many benefits, and there are a few things to keep in mind when choosing this method. In this article, we will discuss three of the most significant benefits of CNC aluminum prototyping.

When CNC aluminum prototyping, machinists must cut the material to precision for optimal results. While the material itself is lightweight, it is soft-textured and can have a lot of applications. Because of its properties, aluminum is widely used for a variety of products. It is strong and lightweight, but it’s also susceptible to damage from excessive chip build-ups. CNC aluminum prototyping is best performed on industry-grade five-axis CNC machines.

Another benefit of CNC aluminum prototyping is that it saves money on shipping. Unlike steel, aluminum prototypes have vast finishes and uniform quality. Aluminum components are also recyclable, making them a cost-effective option for prototyping. CNC aluminum prototyping is also much more cost-effective than outsourcing. CNC aluminum prototypes can be reworked on time without having to produce entirely new parts. Consider the electronics industry as an example. Aluminum is used in the manufacture of the electronics housing. It gives the product a premium look and feels.

CNC aluminum prototypes are inexpensive and durable compared to plastic parts. Compared to plastic, aluminum has a low density and is more durable. It can be processed into different profiles and features. Metal prototypes also look better than plastic parts, and if done correctly, can be made into a finished product.

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español