1: When recevied customer inquiry , our sales will forward the drawings to engineers check it, if we can do it , our engineers will give the price to sales , then our sales make a detail quotation to customer . if we can’t do it , we also will give feedback or advcice cutomer…

Archivos de Categoría: Creación rápida de prototipos

AIXI Hardware offer prototype and low Volume Manufacturing in China , We can offer a fast delivery and shipment , ensure you can received them same time with your local facotry . and you can get a lower machining cost in China , so this is very good choice when you choose global supplier ….

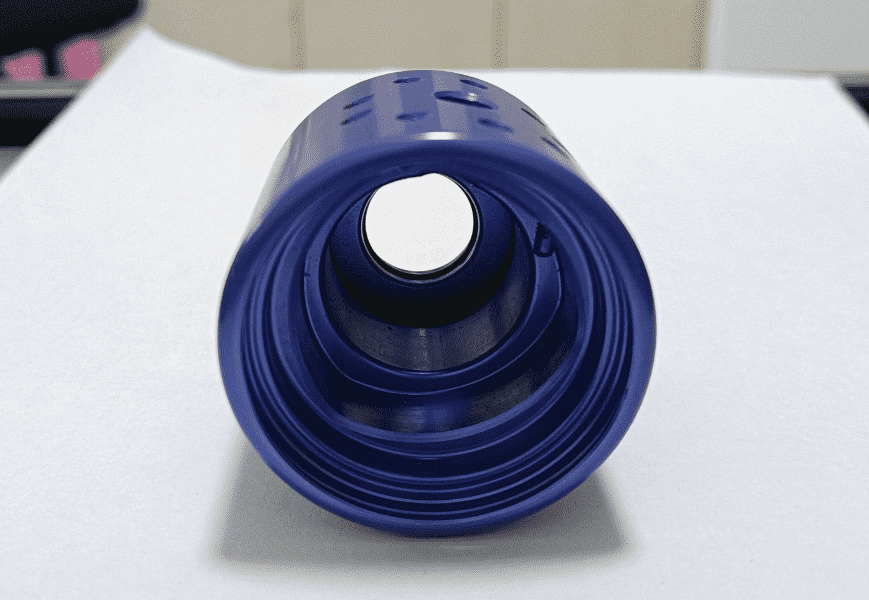

AIXI Hardware focus on prototype machining services , and have a hugh machining capabilities, has around 50sets five-axis machines and three-axis machines . Usually machining material as below : For metal : CNC milling aluminum 60% CNC milling stainless steel / Iron 20% CNC milling brass 15% CNC milling titanium, copper, magnesium 5% For Plastic…

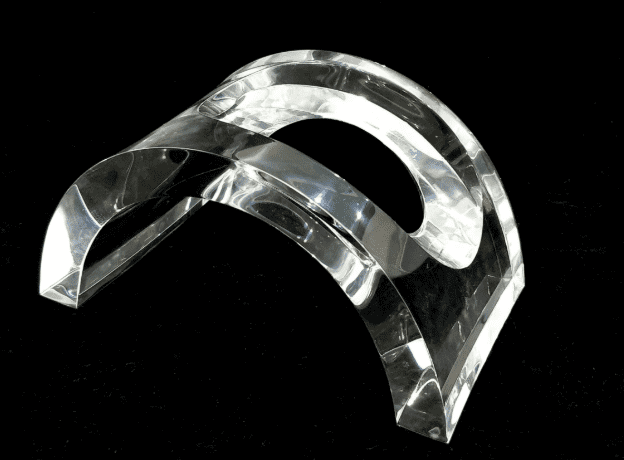

Acrylic display stands, as a relatively high-quality plexiglass, have been widely used in the production of various crafts and display stands. Among them, there are about six types of acrylic display rack manufacturing processes: 1. Mosaic method: According to the design drawing, use a laser cutting machine to cut the different colors of the acrylic…

The common acrylic bending in life is basically a thinner plate to be bent after heating, and local bending can be directly heated on the bending machine and then bend; then what if it is a thicker plate? What to do? Let AIXI Hardware explain to you: The overall bending process of 18MM thick acrylic…

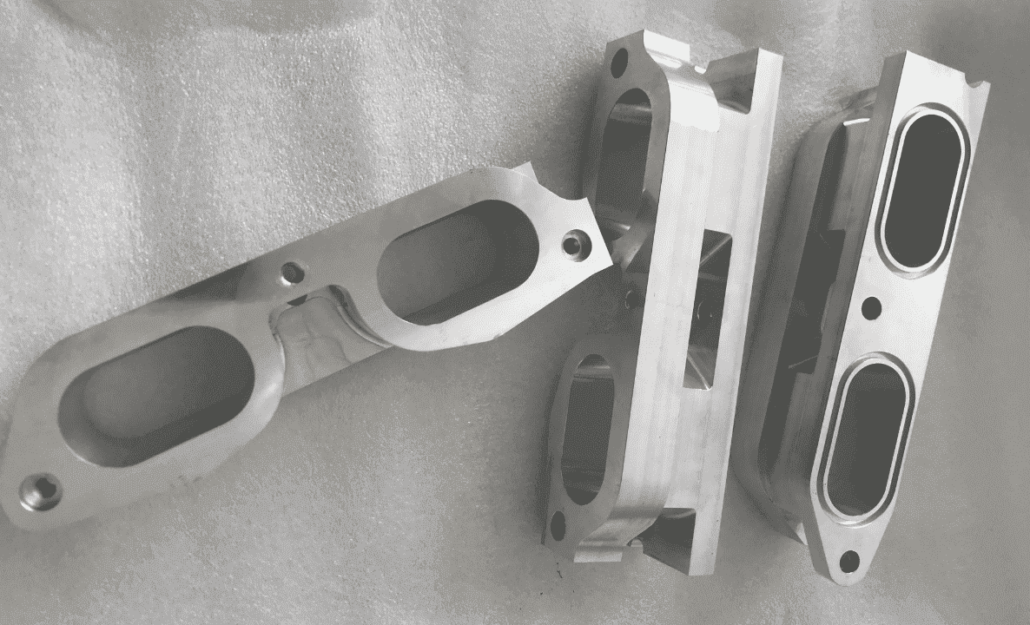

When many CNC precision machining companies develop new products, they will first create a model to verify according to the design drawings. This process is generally referred to as CNC precision aluminum part machining model proofing. Mainly to verify whether the design of this CNC precision machined product is reasonable. The CNC precision parts processing…

10 years ago, the foreign trade business was really very good, because the manufacturing and processing companies are relatively small, the competitive pressure is very small, even I heard from their predecessors that doing PI can be soft, send a development letter, it will I got a reply from a foreign customer. I can imagine…

Acabado de superficies, BLOG, Conocimiento de los materiales, Conocimientos de soldadura, Corte de alambre, Corte por láser, Creación rápida de prototipos, Die Casting, Fundición al vacío, Herramientas de inyección, Impresión 3D de metales, Industria automotriz, Industria de auriculares, Industria del audio, Material de plastico, Material metálico, Mecanizado CNC, Mecanizado de torneado y fresado, Piezas de sujeción, Plástico de impresión 3D, Procesamiento de engranajes, Seguro de calidad, Servicios de chapa metálica, Servicios de estampado, Servicios de extrusión, Sin categorizar, Termoformado, Tubo/tubo curvado

Talk the surface treatment

1: anodizing In order to enrich the color of the product, we can usually make some oxidation treatment. The oxidation treatment can make all the colors except white. The oxidation treatment is done for the aluminum alloy. If it is other materials, it can’t make anodization. Steel material, you can choose plating, etc. anodized aluminum,…

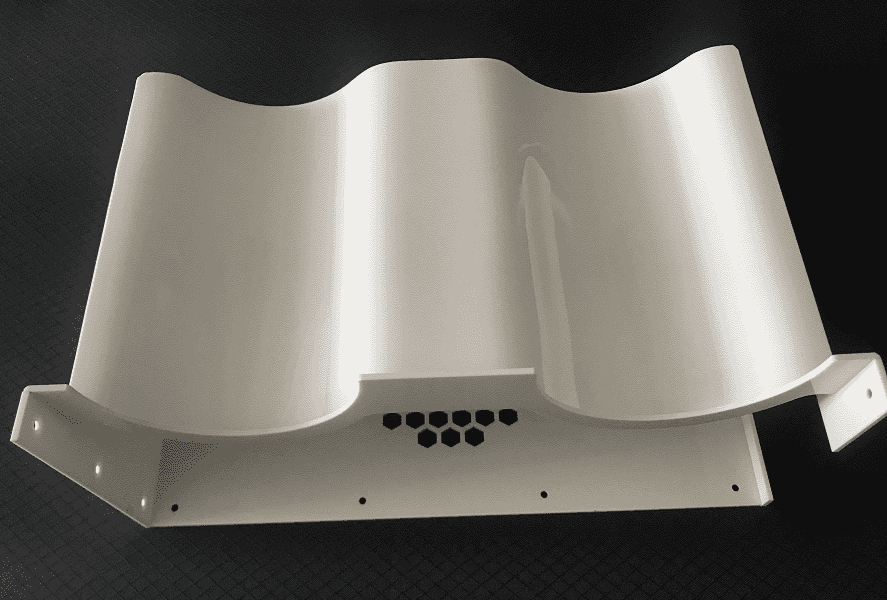

With the formation of global market integration, the competition in the manufacturing industry has become increasingly fierce, and the speed of product development has become a major issue. In this case, the ability to automate rapid product development (rapid design and rapid processing), namely rapid prototyping, has become a strength in global manufacturing competition. At…

Rapid prototyping (SLA) is a discrete/stacking process. It proposes a new thinking mode dimension model from the molding principle, that is, the three-dimensional model of the parts made on the computer is meshed and stored, and layered to obtain the two-dimensional contour information of each layer section. The contour information automatically generates a processing path,…

English

English Deutsch

Deutsch Français

Français 日本語

日本語