Can You CNC 6061 Aluminum?

There are many different alloys made from aluminum, but there is one grade that is particularly well-suited for CNC machining: 6061. This grade of aluminum is commonly called «tooling plate» and has the right properties to maintain a high level of flatness. However, 6061 is still the most popular aluminum grade for CNC machining. This article explores the properties of 6061 to help you determine if it’s right for your CNC machining needs.

Aluminium 6061

Aluminium 6061 is a common type of aluminum alloy, produced through a combination of heat treatment and stretching. Its alloy properties include high strength, good oxidation resistance, and easy fabrication. Its products are used extensively in industrial structural applications. In contrast, 7075 aluminum is more expensive and is used for aerospace and military applications. Both of these types of aluminium alloys can be CNC machined. This article will discuss the two main types of 6061 aluminum and how they differ.

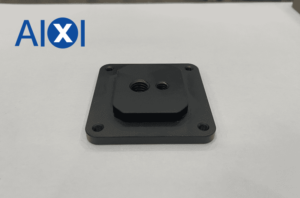

Al6061 is one of the most widely used aluminum alloys. It has excellent machinability, a high strength-to-weight ratio, and superior corrosion resistance. These properties make 6061 an ideal choice for a wide range of applications. Its versatility makes it easy to process, weld, and paint. These qualities make 6061 aluminum a desirable choice for CNC machining. If you’re interested in CNC machining of aluminium, contact us at AIXI Manufacturing.

Cutting speed refers to the speed at which a tool is moved across a workpiece. Aluminium alloys can handle high cutting speeds. However, the speed must be within the limits of the machine. High cutting speeds reduce the risk of built-up edges and ensure less temperature rise of the part. They also improve chip breakage and finishing. The exact cutting speed depends on the diameter of the tool and the aluminium alloy. This article explains some of the important factors that influence cutting speed.

Al-Zn-Mg

Aluminum 6000 series is a four-digit alloy with the main alloying elements of magnesium, silicon, and zinc. This alloy has a high weldability and is one of the strongest among aluminum alloys. It is widely used in various industrial structural parts. It is a four-digit alloy with two phases: the strengthening phase and the Mg2Si phase. The first digit is used to distinguish material grades within the same series, while the last two digits have no special meaning.

If you’re wondering, «Can you CNC 6061 aluminum Al-Zn alloy?», you’ve come to the right place. This heat-treated aluminum alloy is widely used in CNC machining. It features a good strength-to-weight ratio and is naturally resistant to atmospheric corrosion. It is also a versatile metal, capable of being welded, anodized, and machined to a high degree of accuracy. It is also widely available.

Both 6061 aluminum and 7075 aluminum are machinable, but one has more advantages. Aluminum 6061 has a higher strength-to-weight ratio, while 7075 aluminum contains more zinc and copper. Aluminum 7075 is more difficult to machine and holds a better surface finish. 7075 aluminum, on the other hand, is a stronger alloy and can be welded. While 6061 aluminum is more machinable and has a higher yield strength, 7075 aluminum is a better choice for some applications. It also has higher tensile strength.

Al-Zn-Mg alloys

This series of aluminum alloys contains silicon and magnesium, and combines the best features of both the 4000 and 5000 series of aluminum. CNC parts made from this aluminum alloy are highly hard, wear-resistant, and have excellent welding and forming properties. Because of these characteristics, this aluminum alloy is a popular choice for aircraft parts and other aerospace components. CNC 6061 aluminum components can be produced by any qualified CNC machining service provider.

The most common magnesium-based alloy is AZ91D, which contains nine percent aluminum and one percent zinc. Its high strength and corrosion resistance make it ideal for aircraft parts. It is also suited for high-temperature applications. Alloys AM60B and AM50A are used in die casting. Alloy 6061 Mg1% offers a superior high-temperature processability and yield strength of 25kg. It is comparable to SS41 steel, and a CNC part made of this alloy can withstand extreme temperatures.

Aluminum with these alloys is often called architectural aluminum. It has a smoother surface than the 6061 aluminum. It is also half as strong as 6061 aluminum, so it is best suited for applications where strength is not the first priority. The alloy is also rated good for forming, anodizing, and machining. A similar aluminum alloy, 7075, is also available and has zinc and copper alloying ingredients.

English

English Deutsch

Deutsch Français

Français 日本語

日本語