Anodizing aluminum Most non-ferrous metals or their alloys can be anodized. Anodizing refers to the electrochemical oxidation of metals or alloys, and non-ferrous metals or alloys (such as aluminum, magnesium and their alloys, etc.) can be anodized. Oxidation caused by substances other than metals as anodes is also called «anodic oxidation». In the actual process,…

CNC machining generally refers to computer digital precision machining, CNC machining lathes, CNC milling machines, and CNC machining iron beds. It is an automatic machine tool equipped with program control. Computer numerical control machine tool is a programmable control automatic machine tool. cnc processing knowledge Create CNC process functions and CNC machining process plans: (1)…

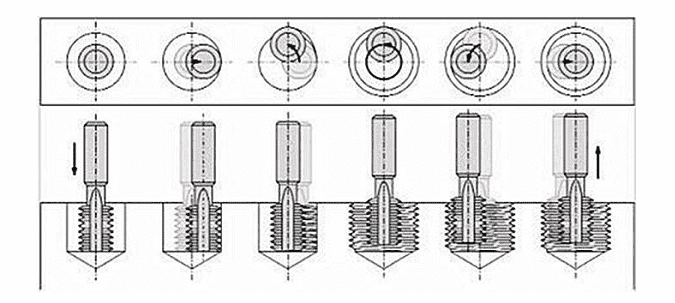

In the turning process of threaded parts, due to the wear and tear of the thread tool, it is often necessary to reload the tool and set the tool. The quality of the tool setting will directly affect the accuracy of thread turning, especially the thread repair turning. , requires secondary clamping and secondary tool…

Differences between ABS plastic and POM: 1. The characteristics of the two are different: 1. Characteristics of ABS plastic: ABS has excellent composite physical and mechanical functions and particularly good low temperature impact resistance. Dimensional stability. Electrical performance, abrasion resistance, chemical resistance, dyeing, finished product processing and mechanical processing are all good. ABS resin has…

17-4PH Executive standard: American ASTMS17400, ASTM A564 630, UNS630 17-4PH is a martensitic precipitation hardening stainless steel. In addition to directly obtaining martensitic structure after solid solution treatment, this steel is further strengthened by subsequent aging treatment-obtaining precipitation hardening phase (copper-containing phase). 17-4PH is a precipitated, hardened, martensitic stainless steel composed of copper, niobium/columbium. This…

AIXI Hardware Wish all customers 2023 Happy New Year !

Commonly used sheet metal materials 1. Cold rolled sheet, SPCC. The most basic sheet metal material is widely used. It is used as the base material of other materials and is relatively easy to rust. 2. Electrogalvanized sheet, SECC, is widely used, and it is obtained by electroplating with cold plate as the base material,…

For AIXI Hardware , we have wonderful engineers for five-axis products , we have made lot of CNC five-axis parts, and always get good feedback . We can CNC machining all kinds of material , for example: aluminum, steel, brass, staninless steel, and PEEK, POM, PA.. If you also have difficult products , or high…

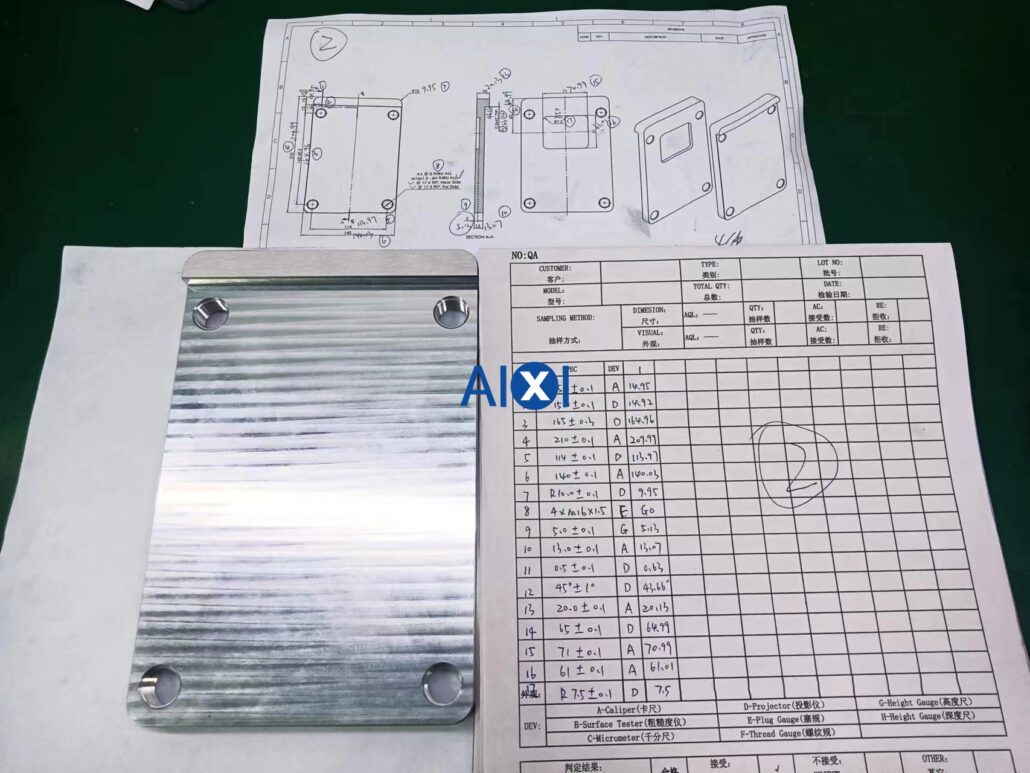

For AIXI Hardware , we will offer inspection diamensions reports to customer confirm before shipment , if everthings is ok , then we will arrange shipment , ensure quality 100% correct before left China . If you also have CNC machining products request, dont heasite to contact us, you can get a compettive price ,…

Surface treatment technology and function of CNC machining (lathe, CNC milling machine) parts, cost of surface finish For each product, specific surface treatments are available for CNC machined parts. However, the surface finish of the product tends to add a corresponding cost. Some finishes, such as high polish, are designed to remove any marks from…

English

English Deutsch

Deutsch Français

Français 日本語

日本語