Sheet metal is a comprehensive cold working process for metal sheets usually less than 6mm, including shearing, punching, cutting, compounding, folding, riveting, splicing, forming (such as automobile bodies), etc.

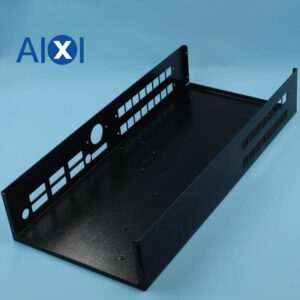

Sheet metal processing is called sheet metal processing. For example, plates are used to make chimneys, iron barrels, fuel tanks, ventilation ducts, elbows, large and small heads, round sky and square, funnel-shaped, etc. The main processes are shearing, bending and buckling, bending, welding, riveting, etc., which require a certain amount of work. Geometry knowledge. Sheet metal parts are thin plate hardware, that is, parts that can be processed by stamping, bending, stretching, etc. A general definition is that parts whose thickness does not change during processing. The corresponding ones are castings, forgings, machined parts, etc. For example, the iron shell on the outside of a car is a sheet metal part, and some cabinets made of stainless steel are also sheet metal parts.

Sheet metal process characteristics

Sheet metal has the characteristics of light weight, high strength, conductivity (can be used for electromagnetic shielding), low cost, and good mass production performance. It has been widely used in electronic appliances, communications, automotive industry, medical equipment and other fields. For example, in computer cases, mobile phones, and MP3 players, sheet metal is an essential component. As the application of sheet metal becomes more and more widespread, the design of sheet metal parts has become a very important part of the product development process. Mechanical engineers must master the design skills of sheet metal parts so that the designed sheet metal meets the requirements of the product. Requirements such as function and appearance can make the manufacturing of stamping molds simple and low-cost.

Common sheet metal material performance characteristics

There are many sheet metal materials suitable for stamping processing. Sheet metal materials widely used in the electronic and electrical industry include:

- Ordinary cold-rolled plate SPCC SPCC refers to steel ingots that are continuously rolled by a cold rolling mill into steel plate coils or sheets of required thickness. There is no protection on the surface of SPCC. It is easily oxidized when exposed to the air. Especially in humid environments, the oxidation rate accelerates and dark red rust appears. The surface must be painted, electroplated or otherwise protected during use.

2 Stainless steel SUS301: The Cr (chromium) content is lower than that of SUS304, and its corrosion resistance is poor. However, it can obtain good tensile strength and hardness after cold processing, and has good elasticity. It is mostly used for springs and EMI prevention.

- Stainless steel SUS304 is one of the most widely used stainless steels. Because it contains Ni (nickel), it has better corrosion resistance and heat resistance than steel containing Cr (chromium). It has very good mechanical properties and no heat treatment hardening phenomenon. elasticity.

- Galvanized steel sheet SECC: The base material of SECC is general cold-rolled steel coils. After the continuous electro-galvanizing production line undergoes degreasing, pickling, electroplating and various post-processing processes, it becomes an electro-galvanized product. SECC not only has the mechanical properties and similar processability of general cold-rolled steel sheets, but also has superior corrosion resistance and decorative appearance. It is highly competitive and substitutable in the markets of electronic products, home appliances and furniture. For example, SECC is commonly used in computer cases.

- Hot-dip galvanized steel sheet SGCC Hot-dip galvanized steel coil refers to a semi-finished product that is hot-rolled, pickled or cold-rolled. It is cleaned, annealed, and immersed in a molten zinc bath with a temperature of about 460°C, so that the steel sheet is plated. It is coated with zinc layer, then tempered, leveled and chemically treated. SGCC material is harder than SECC material, has poorer ductility (avoid deep drawing design), thicker zinc layer, and poorer weldability.

Sheet metal process

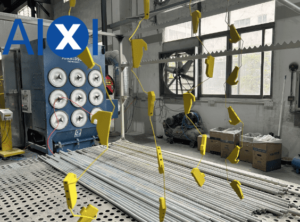

Generally speaking, the basic equipment for sheet metal technology includes shears, CNC punches, lasers, plasma, water jet cutting machines, bending machines, drilling machines, etc.

Auxiliary equipment includes: decoiler, leveling machine, deburring machine, spot welding machine, etc.

The five most important steps in the sheet metal process are blanking, bending, stretching, welding, surface treatment, etc.

- Cutting: mainly punching and laser cutting. CNC punching refers to processing by CNC punching machine. The thickness range of the plate is: cold-rolled plate and hot-rolled plate ≤ 3mm, aluminum plate ≤ 4mm, stainless steel ≤ 2mm. There are minimum size requirements for punching, and the minimum size is related to the shape of the hole, the properties and thickness of the material. Laser cutting is a laser flight cutting process. The processing range of plate thickness is ≤20mm for cold-rolled plates and hot-rolled plates, and ≤10mm for stainless steel. The advantage is that the thickness of the plate is large, the shape of the workpiece is cut quickly, and the processing is flexible; the disadvantage is that it cannot be processed into shape, mesh parts are not suitable for processing in this way, and the processing cost is high.

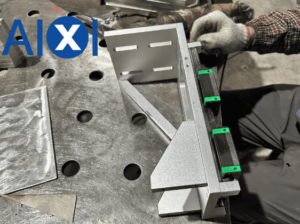

- Bending: Bending parts have a minimum bending radius. When the material is bent, the outer layer is stretched and the inner layer is compressed in the rounded corner area. When the thickness of the material is constant, the smaller the inner bending radius, the more severe the tension and compression of the material will be; when the tensile force of the outer layer exceeds the limit of the material, breakage and breakage will occur.

- Stretching: The radius of the fillet between the bottom of the stretched part and the straight wall should be greater than the thickness of the plate. The thickness of the material after stretching will change to a certain extent. The center of the bottom generally maintains the original thickness, and the material becomes thinner at the rounded corners of the bottom. , the material becomes thicker at the top near the flange, and the material becomes thicker at the rounded corners around the rectangular stretched piece.

- Welding: mainly arc welding and gas welding.

Arc welding has the advantages of flexibility, maneuverability, wide applicability, and can be welded in all positions; the equipment used is simple, durable, and has low maintenance costs. However, the labor intensity is high and the quality is not stable enough, which depends on the level of the operator. Suitable for welding carbon steel, low alloy steel and non-ferrous alloys such as copper and aluminum above 3mm.

The temperature and properties of the gas welding flame can be adjusted. Compared with arc welding, the heat source is wider than the heat affected zone, the heat is not as concentrated as the arc, and the productivity is low. It is used for welding thin-walled structures and small parts. It can weld steel, cast iron, aluminum, copper and their alloys. , cemented carbide, etc.

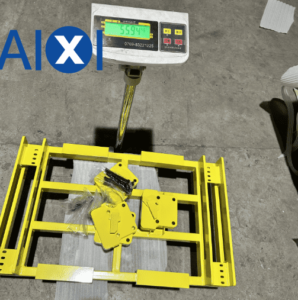

- Surface treatment: The surface pre-treatment of sheet metal parts is mainly to remove oil stains, oxide scale, rust, etc. to prepare for surface post-treatment. The post-treatment is mainly to automatically spray oil on the surface of the hardware through machines such as ovens. Powder spraying, spray (baking) paint, plastic spraying and anti-rust coating, etc. Its purpose is to prevent parts from rusting, make the appearance of the product bright and beautiful, and meet the needs of packaging and shipment.

Modern sheet metal processes include: filament power winding, laser cutting, heavy machining, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending, die forging, water jet cutting, precision welding, etc. .

Sheet metal process design tops

While meeting the functional and appearance requirements of the product, the sheet metal design should ensure a simple stamping process, easy manufacturing of stamping molds, high sheet metal stamping quality, and dimensional stability. The following points should be noted when designing the process

- Materials: Materials should meet the technical requirements. (For example, if the material is cold-rolled steel plate, serious scratches, scratches, impurities, and rust spots are not allowed on the surface.)

- Equipment and process equipment and tools.

Board, pliers, oil can, screwdriver, hammer.

Vernier caliper, outer diameter micrometer, steel ruler, steel tape measure, square ruler, scoring needle.

- Process preparation

Be familiar with drawings and relevant process requirements, and fully understand the geometric shape and size requirements of the parts being processed.

Collect materials according to the material specifications required in the drawings, and check whether the materials meet the requirements of the process.

In order to reduce consumption and improve material utilization, it is necessary to adopt reasonable calculation and tailoring methods.

Stack qualified materials neatly next to the machine tool.

Add oil to each oil hole of the shearing machine.

Check whether the shear blade is sharp and tight, and adjust the blade gap according to the thickness of the sheet.

English

English Deutsch

Deutsch Français

Français 日本語

日本語