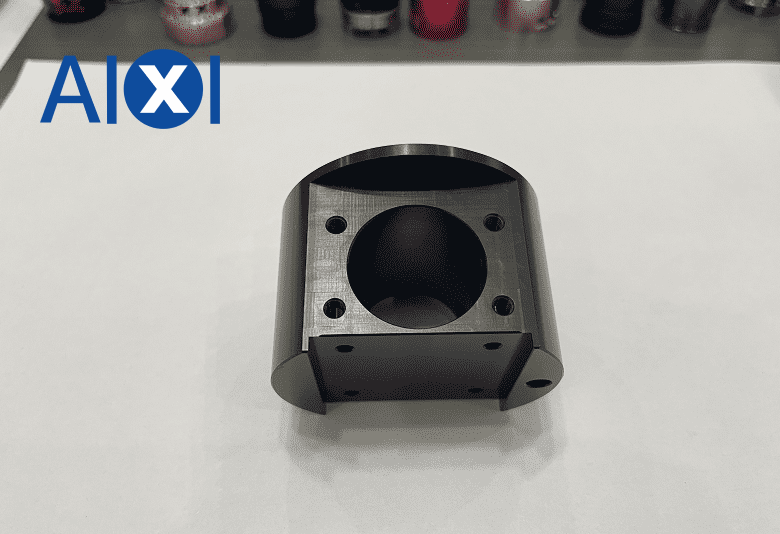

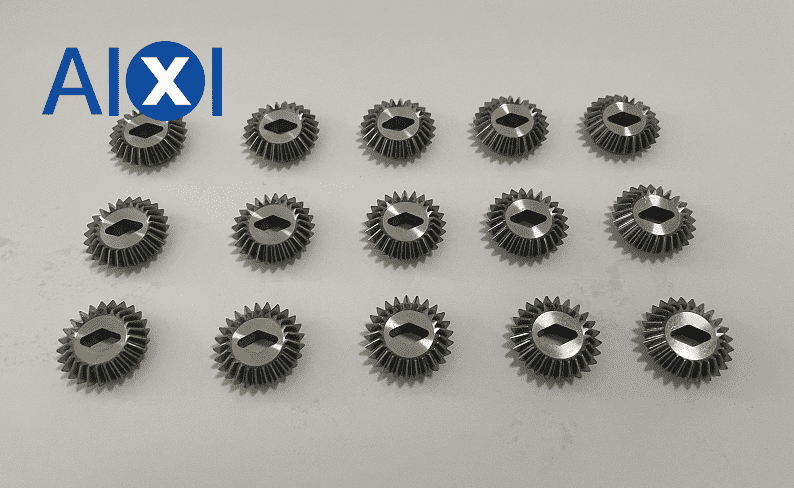

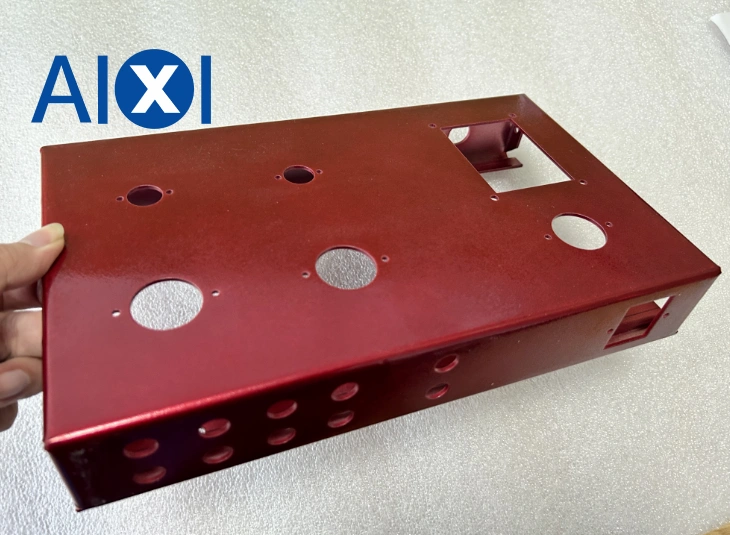

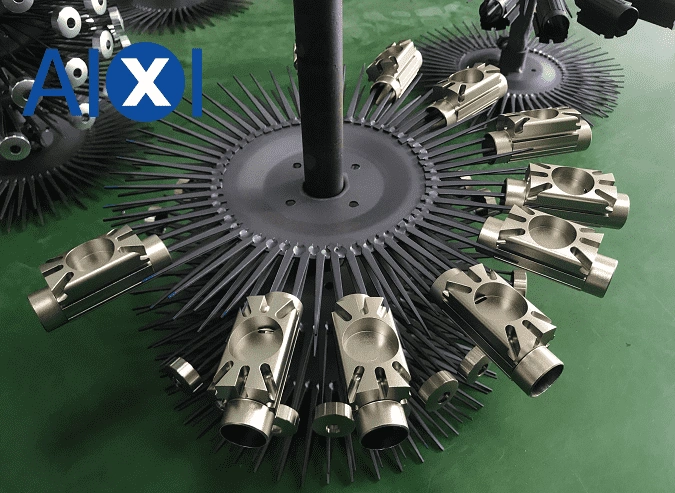

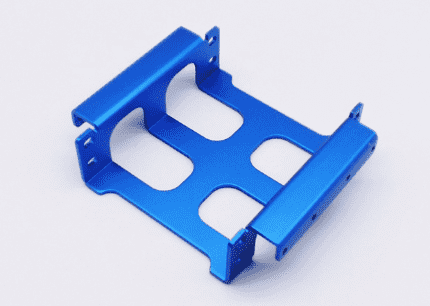

CNC Machining

AIXI specializes in CNC machining and has extensive experience in CNC custom parts manufacturing. From CNC turning processing to 3/4/5-axis milling machining, our factory can realize it all in one stop.

Learn More- -CNC machining enables the production of products with high precision tolerances (±0.01mm)

- -Machining prototype parts can be delivered globally in as fast as 3 days

- -For CNC machining, larger quantities can be more economical

Deutsch

Deutsch Français

Français 日本語

日本語 Español

Español